Hi, I’m Alex Genders. I recently began my commercial apprenticeship at JC Metalworks.

After completing my CTEC in business last year, I felt this opportunity aligned with my career goals. My apprenticeship started on September 4th, 2023. Although initially nervous, I am now positive I will receive helpful guidance throughout the 18-month program.

Inspiring Induction

The induction phase has been an eye-opener, offering a 360-degree view of the business. I’ve had hands-on exposure to both the office and the shop floor. I had never been to a metal fabrication shop floor before. It was fascinating to see all the CNC machines in action, producing a wide range of metal parts and products. I have also been introduced to the digital management systems used at JC Metalworks, which include MIE Trak Pro MRP system and smartsheet, which I think makes the entire operation more accurate and efficient.

Week 1

The First week was mostly about introduction to the company and becoming familiar with the people, departmental roles and responsibilities.

On Monday, Jake the Apprentice Coordinator at JC Metalworks, gave a company-wide presentation which introduced us to the company as a whole, including its capabilities, services, and the industries it caters to. Following the presentation, I had a meet and greet session where I was introduced to everyone in the office, including a brief introduction to their respective roles. Everyone warmly welcomed the other two new apprentices and me, and during the session, we were provided with our workwear and informed about the importance of wearing the right PPE while on the shop floor.

Tuesday was about the introduction to the HR department and the code of conduct handbook, which provided us with an insight into the company policies that we will have to comply with. The handbook will be available for future reference.

During the training session on Wednesday, Duane provided us with detailed health and safety information. He highlighted potential hazards and demonstrated how to stay safe. I applied the knowledge that I gained from the training to conduct risk assessments on the shop floor. Following this, I attended a manual handling briefing by Fabian in the meeting room. Fabian explained the procedures, and to ensure we understood, we completed a test before moving on. The training sessions were very informative and helped me to feel more confident in maintaining a safe working environment.

On Thursday, Neil the Commercial Manager, gave me an introduction to JC Metalworks’ company-wide strategy, including the company’s vision and values, and potential target markets. We also discussed my role as a commercial apprentice, this was very interesting and useful.

I, along with two other apprentices, had a brief office induction on Friday. The induction introduced me to all the departments and operations within the organisation. During the induction, I spent some time with Satish from Engineering, Alan from Quality, Steve from Sales, Nitu from Marketing, Steph from Purchasing, and Mehdi from Estimating.

My Mentor

Having a mentor is a great concept for an apprentice since it’s their first job and a completely new domain in life. A mentor helps the apprentice transition smoothly from being a student to becoming an employee. Steve is my mentor, he is very friendly and talks about everything about my apprenticeship, I feel very comfortable sharing my new experiences with him. Every Friday, I will have a 30-minute catch-up session with my mentor, During these sessions, we will discuss my progress and ensure that I am on track. These sessions will be valuable as they will provide me with feedback on my work and highlight areas for improvement. Additionally, they will allow me to build a strong relationship, which is essential in the business.

Week 2

Cutting Department

I observed Marcin and his team in the cutting department on my first day on the shop floor. It was fascinating to see the advanced machines they use with just a few button presses. I learned about the process cycle of cutting metal sheets to create metal parts through a Fibre laser cutting and punch machine.

Forming Department

I worked in the forming department with Duane on my second day. He showed me how each person has a specific job to ensure timely delivery to the next department. I observed one of the operatives and learned to insert rivet nuts into metal and expand them with a drill gun. It was a valuable learning experience.

Fabrication/ Welding Department

The following day, I was assigned to the fabrication department. Since the company places a high priority on worker safety, I was not allowed to perform any hands-on tasks in this department. After being given a tour of the facilities, I was moved to the forming department for half of the day, and the remaining half of the day, I was given the opportunity to gain some insights into the powder coating department, which would take place on Friday.

Assembly and Dispatch Department

I worked in the Assembly department next, where my main task was to assemble metal parts using hand tools and progress the part to the next stage of assembly. However, my college schedule restricted the time I spent in this department.

Powder Coat Department

I spent my last day of the week working in the Powder Coating Department. Earlier in the week, I had the opportunity to gain some hands-on experience in this department. I kicked off my day with a simple task of using bungs to shield certain parts of the metal that were not meant to be painted or coated. Afterwards, I removed the powder-coated metal parts from the line and placed them on a pallet. The guys in powder coating were a joy to work with and always kept the atmosphere light with their sense of humour and jokes. They demonstrated that even in a work setting, where tasks can be tedious and dull, you can create a positive experience for yourself and those around you.

Overall, I was really amazed by the high-tech stuff at JC Metalworks. Like, they have this super cool Amada Ventis laser cutter machine that can load and unload metal sheets and parts, all by itself. It makes things go faster and can work non-stop for 24 hours! Equally fascinating was the sight of robotic welding and automatic powder coating, where automation took precision and speed to a whole new level, and it’s pretty awesome to see.

WEEK 3

Next on my Induction schedule were all the departments in the Office.

This week , I’ll be spending time in the office. Similar to when I was on the shop floor, I’ll be spending a day in each department. This will allow me to experience each department and help me decide which department to pick for my specialisation. I will spend a day in six different departments.. This process will extend into the following week until Tuesday.

On Monday, while in the office, I worked alongside Nitu in the marketing department. This was to help me transition into the department as I started my new role there on Wednesday.

I gained insight into Nitu’s daily routine. Later that day, I attended a CRM meeting, which provided valuable information about an important aspect of the business impacted by marketing and other departments. Nitu was incredibly helpful, answering my questions and providing support as needed. Her guidance helped me feel more confident in my work, ensuring the job was completed successfully.

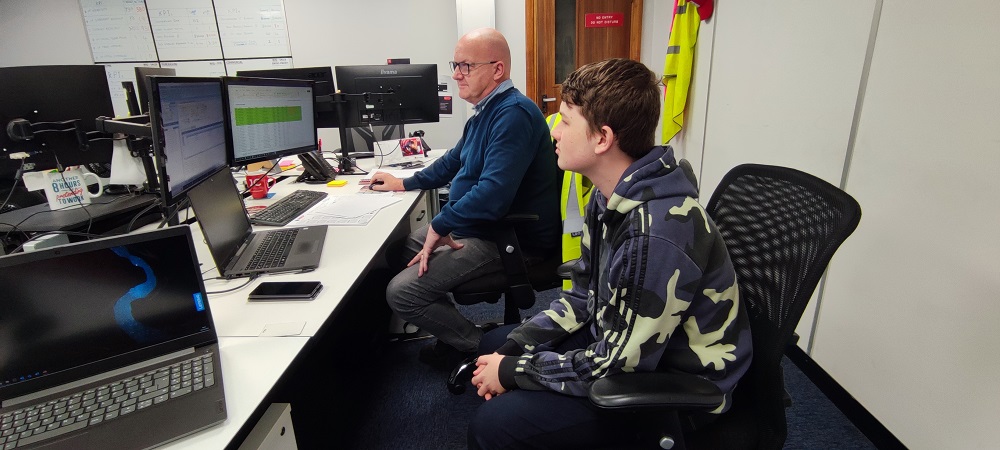

On Tuesday, I worked alongside Steve in the sales/account management department. During our weekly mentor catch-up on Friday, he had given me an idea of what we were going to do that day, so I had some prior experience. Our focus was on the MRP System JC Metalworks uses, MIE Trak Pro. We mainly focused on what the estimators do, which was helpful for me because I had been confused about how MIE works since my Induction week. Steve was effective in helping me understand the system by allowing me to work with it and answering my questions when needed. He knew a verbal explanation would not work for me, so he took a different approach. Thanks to his help, I feel more comfortable using the system and confident that with a little guidance, I will be able to complete tasks using MIE.

Next, I worked in the sales processing department with my colleague Fran. It was a great experience and I found it very useful. Throughout the day, we completed various tasks such as getting data ready for the CRM and making necessary changes, adding important information like the county where each business is located, and verifying the accuracy of addresses. We also processed POs and assigned them to respective engineers, with Satish : Scheduling the work to the other engineers.

This experience benefited me because it allowed me to learn more about Fran’s department and the tasks she handles. Additionally, since Fran sits next to me in the office, when I have completed my assigned work I can assist her with processing daily POs. Fran is a kind and helpful colleague who guides me through the tasks whenever I am unsure.

On Thursday, I had College so I wasn’t assigned a set department for that day once I had completed College for the day and did some of the given homework, Fran let me go into her department to give me something to do and be useful.

Friday, I was with Steph in the purchasing department, and I gained an understanding of the purchasing process. She explained the difference between direct and indirect spending, and I assisted her in accurately storing purchasing-related documentation. Steph was helpful and made me feel confident in performing the task.

WEEK 4

On the Monday following that, I had the opportunity to shadow Satish in the Engineering department. Although I didn’t participate in their work, observing them was informative and helpful. I gained a better understanding of their daily tasks. After Satish, I spent some time with Joe, who taught me about nesting and how they input various types of information into the system and then transfer it to the shop floor for manufacture. After spending time with Joe, I was introduced to Theo, who was interacting with a customer on the shop floor. Observing him provided me with insight into how he handles client interactions. Everyone was welcoming and friendly, and I appreciated the opportunity to shadow them to prepare for the upcoming week.

On Tuesday, I spent time with Mehdi in the estimating department. Similar to my experience in the engineering department, I observed and shadowed their work rather than actively participating in it. During this time, I learned how to use MIE and saw how different people preferred different ways of using the system. After Mehdi’s thorough explanation of estimating, I was introduced to Bekki and David which gave me a better understanding of how the system works.

Starting this Wednesday, I will begin my commercial carousel learning program, which involves spending a few weeks in each department and learning all the concepts included in my syllabus. My first four weeks will be in the marketing department, working with Nitu.

The amazing Team-Building day

On Thursday, I was given permission to miss college so that I could go to the event and get to know my colleagues better. I planned a catchup with my college on the following Monday. This was a great chance for me as a new Commercial Apprentice to engage in a fun team-building activity with all the departments. I was lucky that this opportunity appeared in my first month here, allowing me to get to know my colleagues and feel like a part of the team. I would love to do this again next year, but with teams made with all departments, mixed up.

All set for some serious work!

During my first month at JC Metalworks, I’ve had a wonderful experience. I’ve had the pleasure of meeting many new people who I’ll be working with for a minimum of 18 months, provided everything goes well. Without exception, everyone I’ve met has been down-to-earth and incredibly kind, particularly those who are with me throughout the day.

As I work in several different departments, it’s crucial that I get along with everyone to make the experience as enjoyable as possible. These departments include Sales, Purchasing, Sales Processing, Estimating, Marketing, Engineering, and Finance. Every team member I’ve encountered has been incredibly welcoming, and even a simple “good morning” or goodbye can go a long way in building strong bonds with others.

I found JC Metalworks very organised and good, though there can be some noise from the punching machine downstairs which is to be expected in a metal manufacturing business. The company has a well-defined quality management system in which all the departments function. They’ve given me a great opportunity to become a commercial apprentice and I’ll do my best to reach my potential and contribute to the company in my job role. After being here for a month, I’ve learned a lot about the company’s operations and teamwork which is very impressive.

Leave a Reply