Metal Fabrication for Heat Pumps

Heat pump system manufacturers are investing heavily in the R&D of innovative technology to provide up-to-date and environmentally friendly heating and cooling solutions in order to tackle climate change. To ensure your business is ready for the increasing demand, a solid partnership with a bespoke metal fabricator is crucial.

The production and processing of metals is an energy-intensive industry. By using less energy, we can help to combat climate change.

Our latest energy-efficient CNC machines for sheet metal processing – Cutting, Forming, Fabricating and Powder Coating – allow us to bulk manufacture at competitive prices with reliable lead times.

We can provide metal fabrication for:

- Ground source heat pumps

- Air source heat pumps

- Water source heat pumps

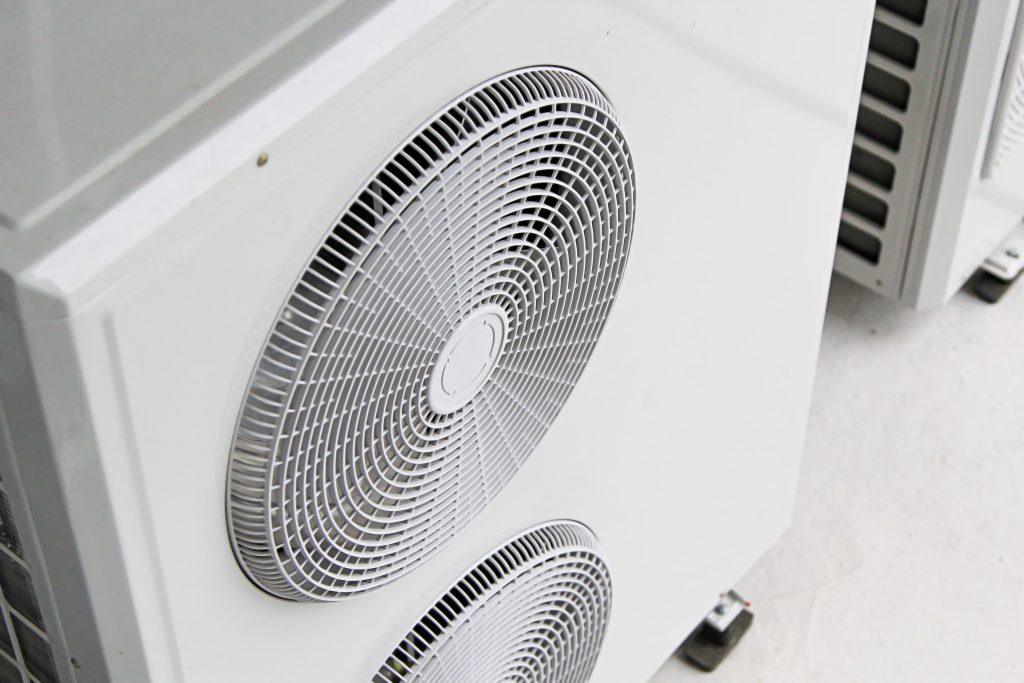

Protective Encasements for your Heat Pump System

Components of a heat pump

Heat pumps all have the same basic components. These components consist of a metal body/encasement; a pump; a condenser; an evaporator; and an expansion valve. Despite the relative similarities of these components, heat pump designs vary greatly depending on the specific application of the pump.

We can manufacture heat pump enclosures to your specifications, bespoke to suit your ground or air source heat pump system.

The Manufacturing Process

The units, encased in a sheet metal box, comprise various subassemblies for the condenser and evaporator in order to bolt every component to the box or to one another. Some of the brackets used form the base of the unit where the pump is bolted down to a metal container and connected to an AC motor.

Most heat pump manufacturers outsource the manufacturing of the metal encasement/enclosure for the unit.

Encasements

- Assembled from several different sheets of metal, encasement units are cut to size by our Amada CNC fibre laser cutting machine. After they are cut to the proper dimensions, small assembly holes are punched in the metal using a CNC punch press. We have automatic punch presses which have different-shaped punching tools stored within, providing the ability to punch all of the necessary holes by simply changing the computer program.

- After punching, the sheet moves to the Forming Department where our CNC press brake bends it into different shapes and configurations by using dies or tooling. We have both manual and automatic panel bending and forming machines. The formed part is then ready to be welded, riveted or bolted to the other sheets and brackets. Once assembled, the highly sophisticated fabrication provides most of the stability to the stand-alone units.

- Components, subassemblies, brackets, and/or plates are then powder coated for corrosion resistance. Once the part is coated, it goes into an oven for curing at about 200 degrees C (400 degrees F) for about 20 minutes. After curing each part goes through a rigorous quality inspection.

Assembly, Packaging and Dispatch

The metal encasements are now ready to be assembled, packed and dispatched to the heat pump manufacturing company for the installation of the internal components.

Metal encasements and enclosures for heat pumps by JC Metalworks

Take advantage of all the benefits of choosing JC Metalworks:

- 35 years of expertise in sheet metal fabrication

- Value Engineering to achieve major cost and time savings

- Prototype design and development

- Seamless transfer from prototype to mass production

- Advanced technology for high-volume sheet metal projects

- Dedicated on-site assembly of a large range of non-metal parts

– electrical, glass, acrylic components, joinery, vinyl graphics

and lighting - A one-stop shop for all your high-quality metal fabrication needs

JC Metalworks is ready to make a big impact in working towards Net Zero by optimising its existing energy-consuming assets through state-of-the-art, energy-efficient technology and equipment. Partner with us for your precision sheet metal subcontracting and benefit from our high-quality manufacturing.

For more information on how we can help you to create heat pump enclosures and systems please submit a contact form or call us on 01509 233280 and we’ll be happy to help.

What Are Heat Pumps and How Do They Work?

Learn all about what heat pumps are, the different types available and how they work.

Latest News

More Bespoke Solutions

Our precision metalwork expertise add value to a wide range of different industries.