What is sheet metal forming?

Sheet metal forming, also known as panel bending, involves a combination of processes to stretch or bend metal into different intricate shapes without sacrificing the strength and durability of the metal.

By modifying the geometry of the steel or aluminium, we are able to bend the material into a variety of different shapes using a smaller amount of material than would be required in other processes. Doing this allows us to reduce metal waste and pass savings directly to our clients.

Where are sheet metal forming processes used?

This process is used in almost all manufacturing industries. The aerospace, automotive industry, construction, electronics and energy sectors often make regular use of panel bending, however, any company that turns raw materials into structures can likely benefit from the sheet metal forming process.

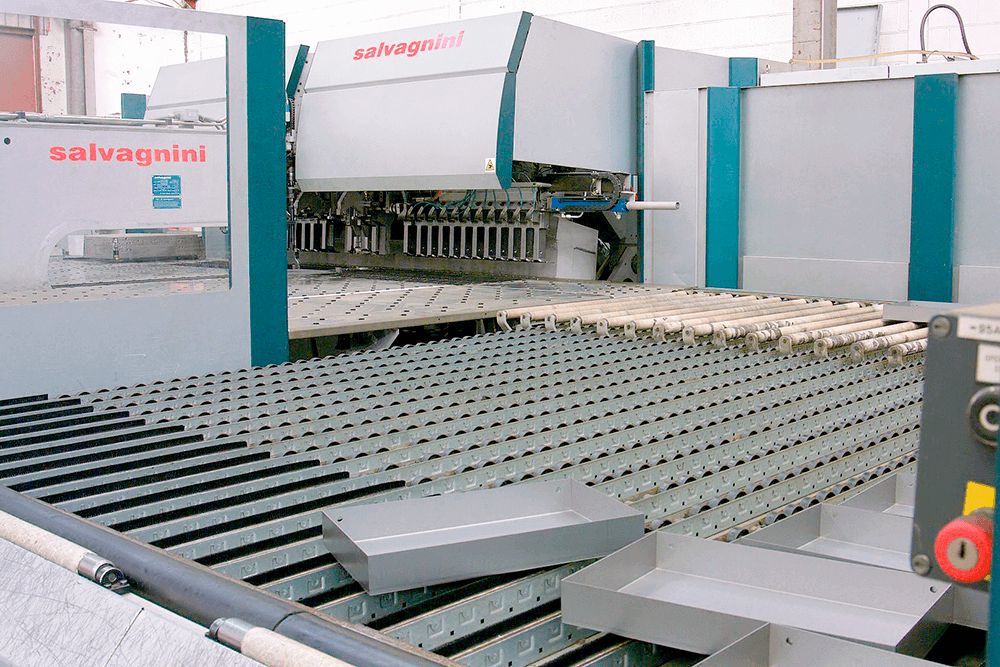

Salvagnini P4X Sheet Metal Panel Bender

Known for its speedy set-up times, fast cycle times and rapid offline programming.

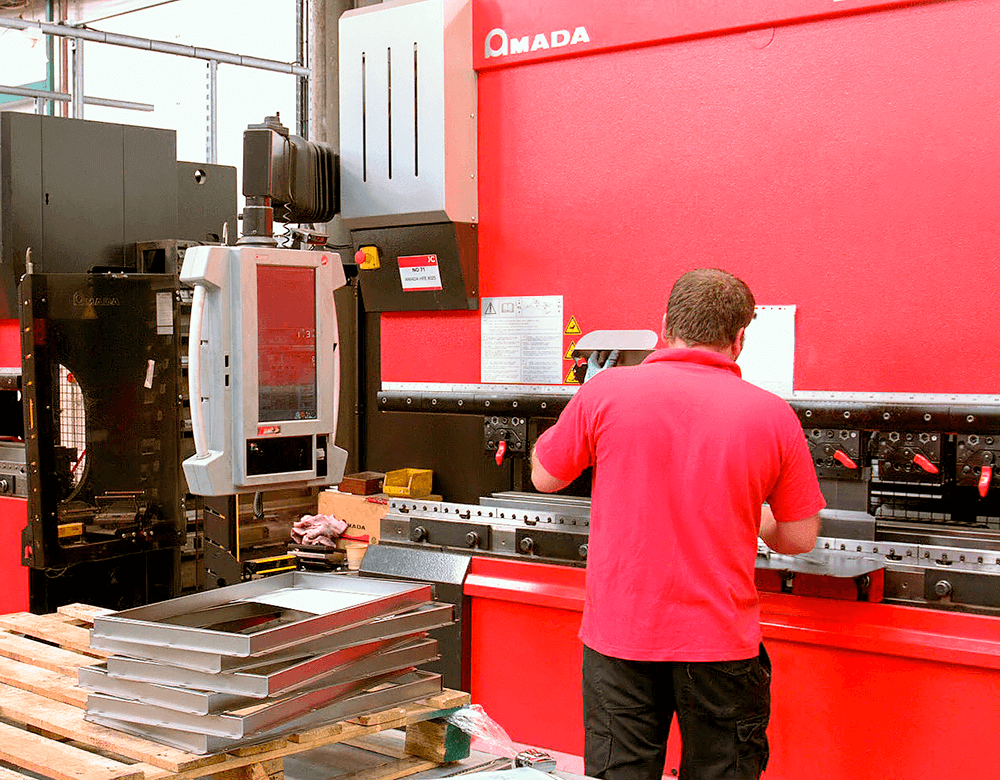

LVD and Amada CNC Press Brakes

With bend lengths of 3m and swift changeover tooling.

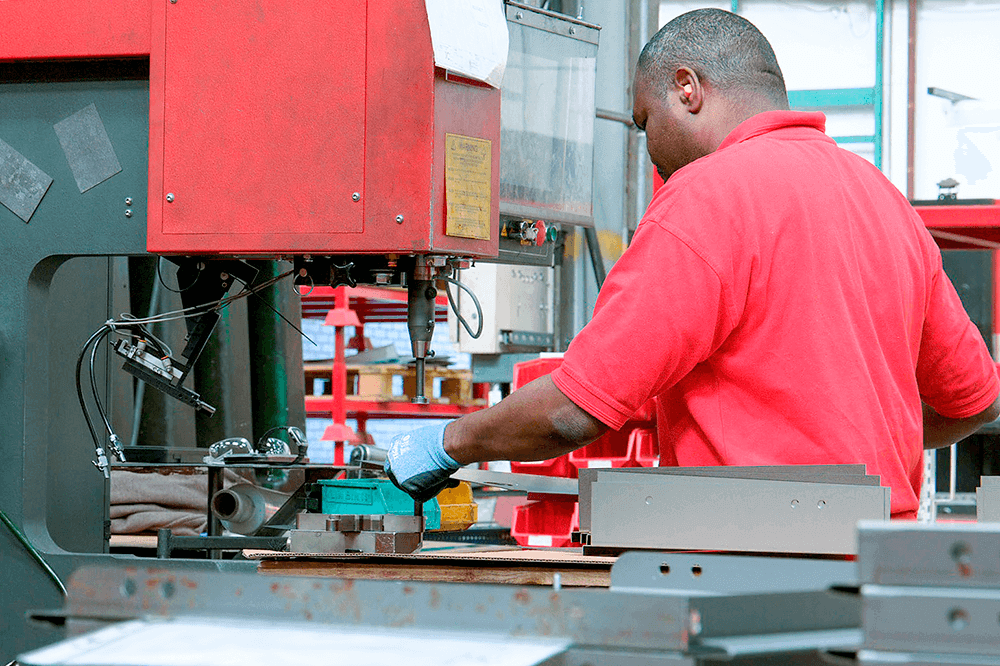

Sheet metal forming at JC Metalworks

At JC Metalworks, we work with aluminium, mild steel and stainless steel sheet, using lean manufacturing and 5s techniques (sort, set in order, shine, standardise, sustain), to ensure top quality, fast turn around and cost-efficiencies for our clients.

We are one of the UK’s leading custom manufacturers and suppliers of high volume, bespoke forming services. We can manufacture large quantities to order with high precision, producing the final form to your requirements.

Having worked in the sheet metal manufacturing industry for over 30 years there isn’t much that we haven’t seen or done with sheet metals.

Our sheet forming projects

We’ve worked with numerous clients on a variety of projects, making use of the following bending methods:

- Bottoming

- Air bending

- Coining

- U-bending

- Step bending

- Roll bending

- Wipe bending

- Rotary bending

Unrivalled metalwork tools

The metal shaping tools we utilise are unparalleled when it comes to reliability and repeatability, allowing us to turn projects around efficiently within compressed timeframes.

If you require paper-thin panel bending, we can offer high-quality parts or components through to a fully finished product each and every time.

We are continually investing in equipment to ensure we remain not only at the cutting edge of our market but remain the Midland’s leading custom manufacturer and supplier of bespoke metal forming.

We can also help with

Through a selection of trusted and approved partners, we can source wire bending and tube forming services on your behalf. Please get in touch with details about your project and we can discuss how we can help.

We can competitively source:

Wire Forming

Typical CNC wire formed products and components that we source from trusted third parties in high volumes include display racks, d-arms, curved headers, chair frames, furniture frames, seat frames, support legs and much more.

Tube Bending

This is an umbrella term for the metal forming processes used when steel pipes or tubes are permanently bent or formed. This is another service that we can source on your behalf from our trusted partners.

We only work with partners that will further enhance the type of products we are able to manufacture, putting the quality of our products and our client’s requirements at the forefront at all times.

Our knowledgeable sheet metal folders will manage your projects to ensure all component manufacturing seamlessly fits into an agreed production schedule. We also offer metal finishing so you can get the surface finish you require.

Knowhow

The Advantages of Sheet Metal Forming

Did you know that 90% of the work we do for clients involves some form of sheet metal forming or metal bending?

Latest News

Our Services

The complete end-to-end solution under one roof.