Aluminium fabrication services

We provide a full-service aluminium fabrication solution, working closely with our customers for a quick turnaround and excellent end results.

Our on-site tools and equipment include:

- CNC cutting: We are capable of accurately and efficiently cutting aluminium to specific dimensions and shapes

- CNC forming: Our Experienced team is able to bend, shape, or form aluminium into complex and precise shapes or configurations

- Welding and finishing: Our welders and Linishers are equipped with the latest techniques for welding and finishing. It also involves the application of surface treatments such as grinding, sanding, or polishing to improve the appearance and functionality of the aluminium product.

- Powder coating: To enhance the appearance and durability of the final product our automatic powder coating system enables us to provide a wide range of colour, varying gloss levels, ripple, textured and even tinted/clear lacquers.

- Assembly: services include tasks such as fastening, connecting various parts and components, installing lighting and electrical fixtures, graphic pasting, screen printing, and applying rubber and silicon sealant.

- Packaging and dispatch: Involve customised and efficient packing of the finished product, often using protective materials such as bubble wrap, foam and cardboard boxes.

Our fabrication process is all taken care of in-house by our experienced and skilled team.

Is aluminium harder to fabricate than steel?

At JC Metalworks, our fabrication services are available utilising numerous metals, however, we specialise in steel and aluminium fabrication. In general, aluminium is considered to be the most challenging metal to work with, as well as one of the most beneficial. Here’s a closer explanation:

What are the benefits of aluminium?

Amongst all metals, aluminium possesses the most advantageous physical and mechanical properties for manufacturing and is also pleasing to the eye. Some of the benefits of this metal regarding fabrication include:

- It is durable and robust,

- It is lightweight and easy to handle,

- It is corrosion–resistant and resistant to any other form of abrasion,

It is unaffected by magnetism, - Aluminium is a great conductor of electricity and heat, and

- It is flexible and versatile – it can be manufactured in any shape and size.

What is the downside to aluminium?

- Aluminium is a reflective material; when light is projected onto it, it bounces back or scatters.

- Its molecular structure renders it malleable,

- It is a heat-conductive material.

Such properties make it a challenging metal to fabricate, but with our latest technology and decades of experience, we have developed effective capabilities to cut aluminium.

Despite the fact that some of its inherent properties can make the fabrication process difficult, our skilled team use the latest technology to produce fantastic results. Our team’s enthusiasm for showcasing their skills to the fullest and finding creative solutions to any complications has made us experts in aluminium fabrication.

Prefer stainless steel fabrication?

We also specialise in stainless steel fabrication.

Why choose JC Metalworks for your aluminium fabrication project?

For more than 35 years, we’ve been proving our expertise and dedication to quality. We’ve built a brilliant reputation as an industry-leading sheet metal fabricator.

Arguably, what makes our service so sought-after is our state-of-the-art equipment and dedication to a fantastic customer experience at a great cost. Here’s a sneak peek at some of the equipment we use for our aluminium fabrication:

Amada fibre laser cutting technology

This machinery allows us to cut aluminium without defects and with a smooth finish. Using a focused, high-speed, fully sealed laser, we remove the possibility of back reflections – a common issue with aluminium fabrication.

This machine allows for cutting tight tolerances, resulting in better edges, better-than-ever turnaround times, and reduced costs.

Two Amada CNC turret punch machines

Punching is a quick and cost-effective way for creating holes, slitting, forming, countersinking, rolling, marking and tapping of varying diameters in aluminium. Our Amada Turret Punch’s automatic online tool changer (which can hold up to 220 tools), speeds up the punching process considerably.

Fast, repeatable and cheaper than drilling, punching is widely used across a diverse array of industries. These two machines ensure that the punching process is as accurate, effective and repeatable as possible. They provide the capability to process a range of thicknesses from 0.5mm to 3.0mm up to 4 mts in length.

Our unmanned, 24/7 capability allows quick turnaround time and on-time delivery.

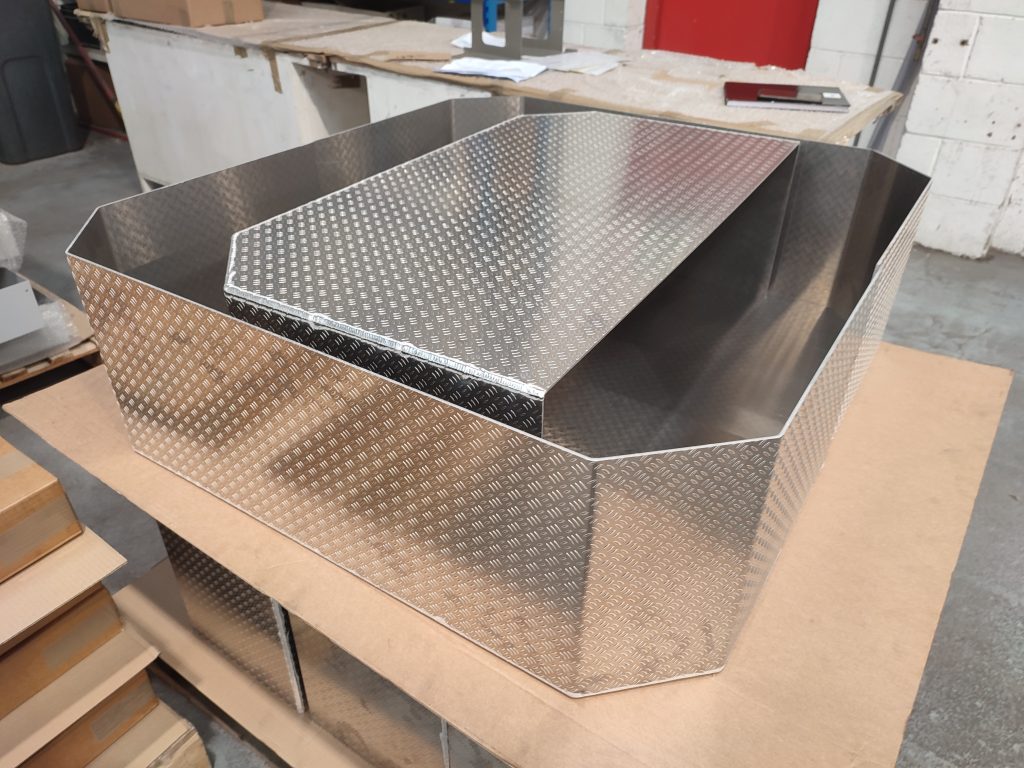

Three Amada Press Brakes, a Salvagini PX4 and an LVD machine for ultimate panel bending

We offer an unbeatable combination of knowledge and capability in the creation of complex curved aluminium products.

Understanding the properties of aluminium is essential to achieving accurate forming. Aluminium is lightweight; durable; robust; corrosion-resistant; malleable; extremely ductile; unaffected by magnetism; and a good conductor of heat and electricity.

The general rule of thumb when bending aluminium is the harder the grade, the more spring back is expected. Our CNC programmable press brakes help us to achieve consistent accuracy in forming and ensure production precision from one batch to the next.

ITW powder coating system

Powder coating is a finishing process in which dry, free-flowing, thermoset powder material is applied to a surface, melted and hardened into an even coating. The process offers several advantages over conventional liquid coating methods including increased durability, capabilities for more specialised finishes, less environmental impact and faster turnaround time.

Here at JC Metalworks, our in-house ITW Gema Powder Coating Facility is fully automated with 6 automatic coating guns and a 2 metre-per-minute track speed.

Aluminium fabricated and linished parts undergo a multi-stage powder coat process, the full cycle for which takes 1 hour 15 minutes.

Our aluminium fabrication process

When we undertake your new project, we will assign a single point of contact to oversee the entire operation, keeping you updated at every stage of the journey. They will also be available to answer any questions you have or offer advice and guidance.

Our aluminium fabrication process begins with a thorough assessment of what you’re looking for. We will take the idea of what you’re hoping to achieve, your budget, time frame and any additional requirements you provide and use all of this information to create a detailed plan of action.

When you’ve signed off on the plan, your project manager will organise our engineers, technicians and production team to start working on fabricating your aluminium project. Whether you’ve requested a single bulk order or a phased rollout of products, you will be notified when milestones are hit, and if we come across any challenges and the resolutions we have planned.

Is aluminium fabrication expensive?

As a metal, aluminium is more expensive than steel to purchase as a raw material. However, if we believe it is the ideal material to use to create the best final product possible, we will recommend it.

While aluminium may be expensive to purchase, there are many advantages to using it in fabrication.

When it comes to specifying precisely how much aluminium fabrication costs, it’s practically impossible to state categorically as there are so many factors that influence the cost of a project. With that said, we strive to offer the most competitive quote possible and are always working to keep costs as low as possible. This includes reducing our material waste and finding efficiencies that don’t influence quality wherever we can.

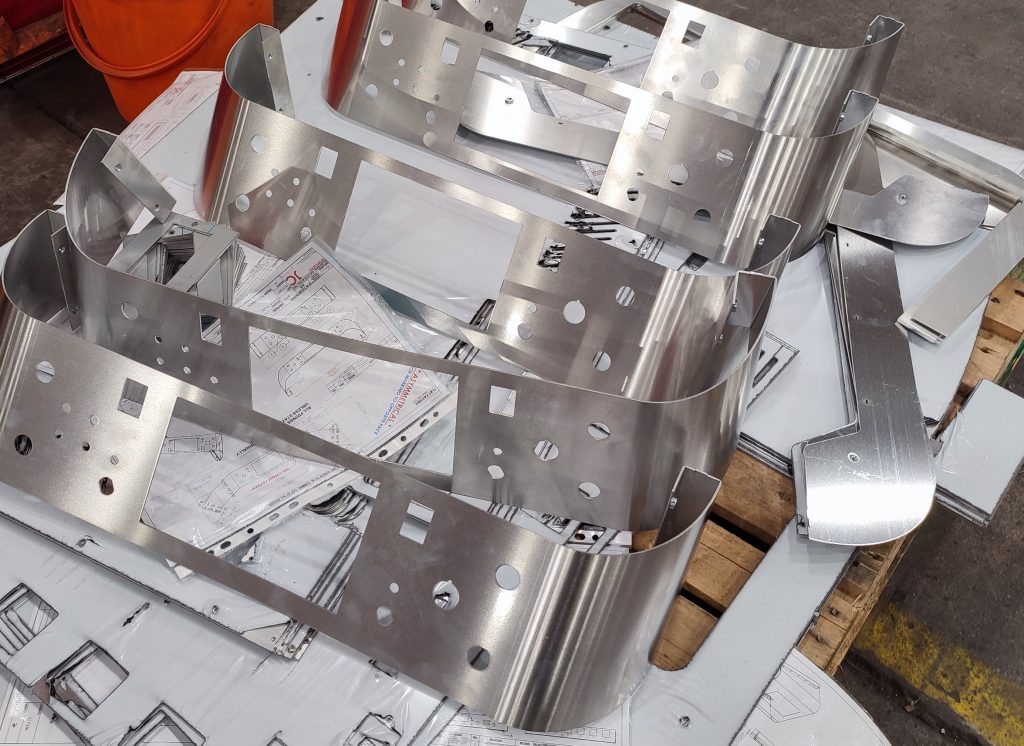

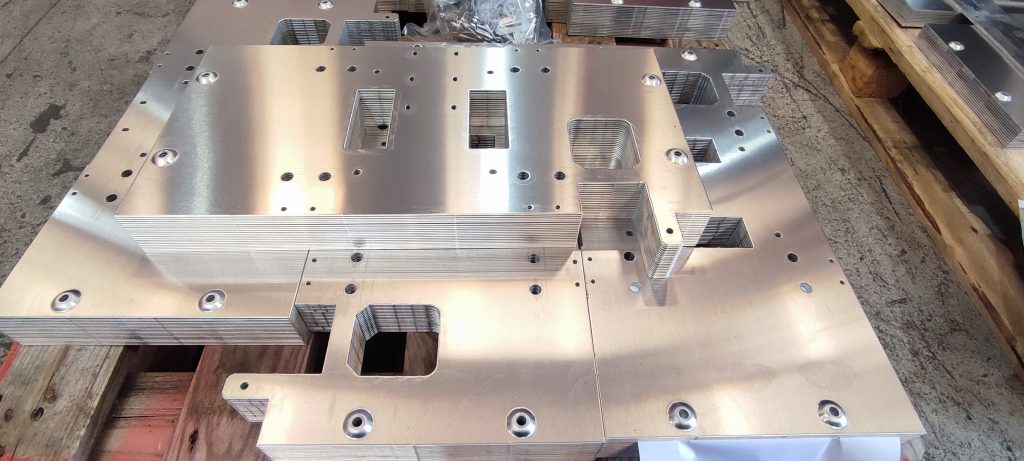

Previous aluminium fabrication projects

We’ve taken on a wide variety of aluminium fabrication projects over the years. Some of our latest projects have involved manufacturing of Scientific instruments, machine chassis, Components of Heating, Ventilation, and Air Conditioning (HVAC) systems, Parts for Digital Kiosk and signages, frames etc.

Knowhow

What Metals are Used in Metal Fabrication?

Metal fabrication is the process whereby individual metal parts are welded together, linished, and dressed, to make them ready for finishing, either with chrome plating or powder coating.

Latest News

Our Services

The complete end-to-end solution under one roof.