Serving the Electric Vehicle Charging Market

The number of electric vehicle networks is growing. More public chargers with fast charging functionality are needed to help EV drivers stay on the road.

JC Metalworks provides precision sheet metal fabrication for electric vehicle charging solutions for home charging, workplace charging and public charging. Metalworks from complete charging stations to manufacturing specific components and supplies, we can help.

We have a wealth of metal fabrication knowledge. We have the experience, capability and capacity to help with:

- Design,

- Prototyping,

- Fabrication, and

- Assembly.

We can assemble complete charging solutions or provide specific components. We have the capability to design electric vehicle charging stations from the ground up to provide smart features, safety protection and fast charging functionality.

How we help the electric vehicle market

Electric vehicle charging stations have strict requirements surrounding the design and manufacturing process. These include:

- Waterproofing – all EV charging solutions must have waterproof IP ratings.

- Trespasser resistant – to prevent damage.

- Fast chargers with surge and overload protection – to protect equipment, electric vehicles and users.

They also need a durable finish in keeping with the modern look and feel of the charging stations.

As EV charging station manufacturers, we keep all of this in mind during the design and manufacturing process.

We can supply you with:

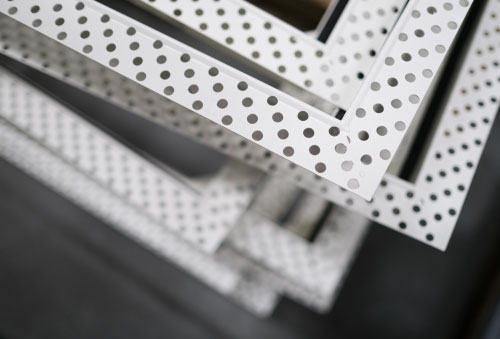

- Customised sheet metal enclosures,

- Power charging pillars,

- Feeder cabinets,

- Station enclosure shells,

- Charger pedestals,

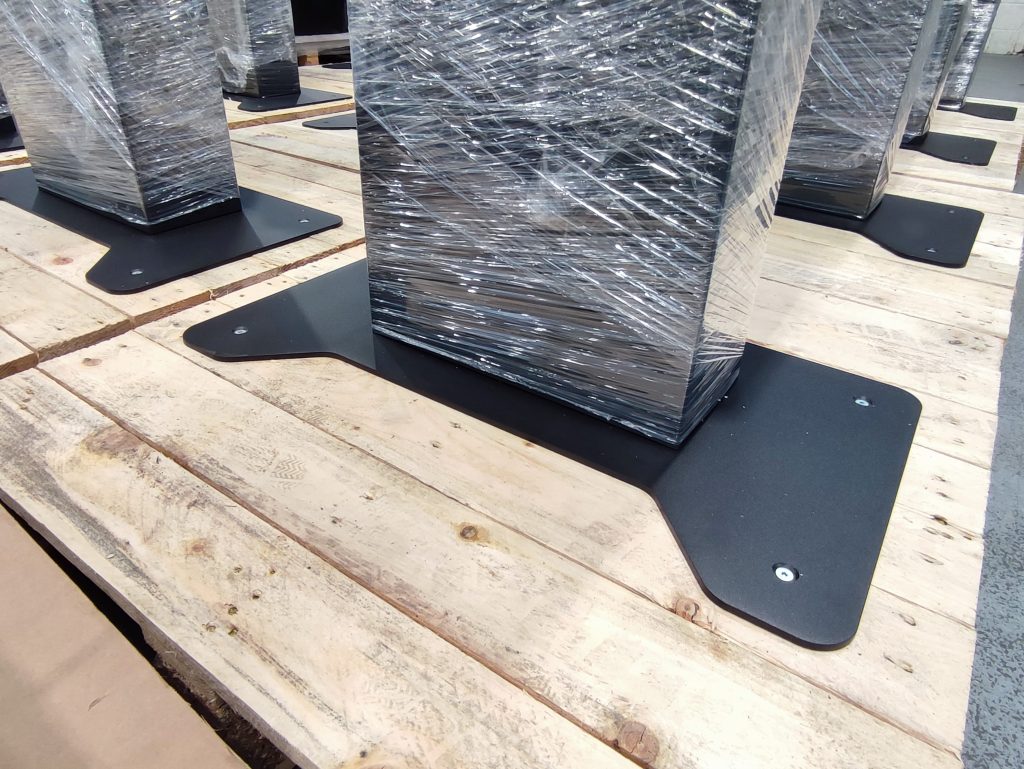

- Custom-mounted bases,

- Rack mounts,

- Stands,

- Metal boxes,

- Customised stainless steel stamping brackets,

- Watertight cabinets and encasements,

- Metal brackets, and

- Metal plates.

Our Electric Vehicle Charging Stations Services

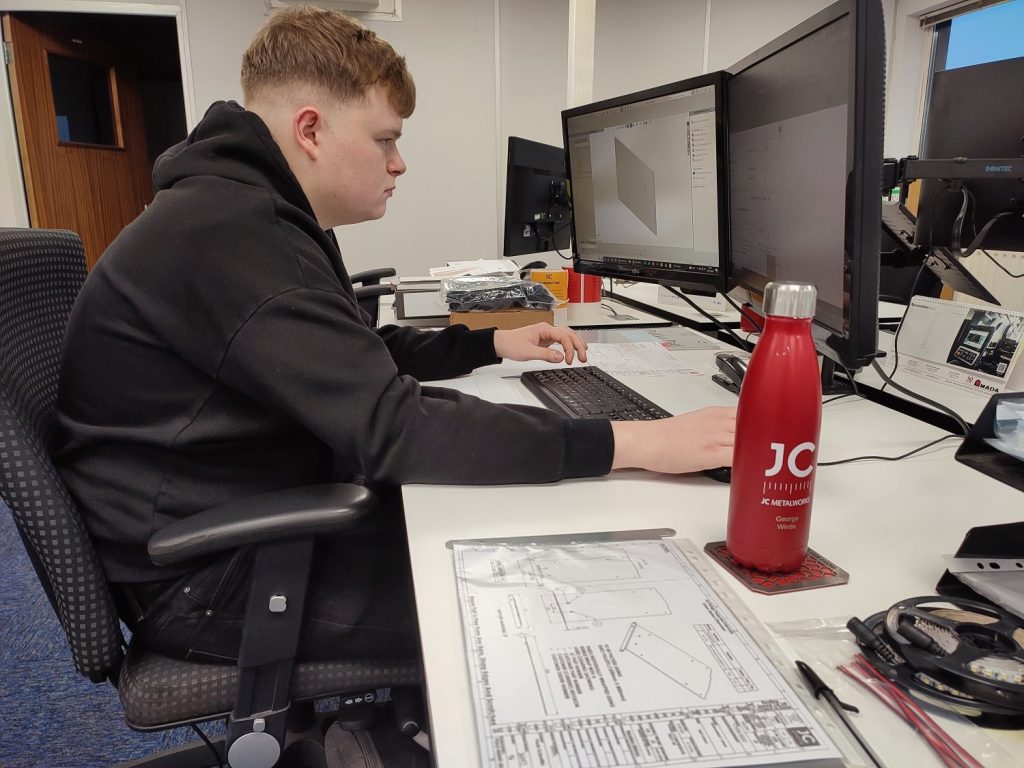

Engineering Design Support

Our specialist project engineers will work with you to create some visuals. They will then turn these into a final prototype specification.

Using modern design software like Solidworks, Radan and Amada, we will prepare the drawings to manufacture and fabricate your charging stations.

Manufacturing Electric Car Charging Solutions

Utilising modern in-house machinery and equipment, we will build your EV charger solutions or assisting components. We work to the highest standards and efficiency.

Metal Cutting and Punching

The cutting department has 2 Amada Fibre Laser cutting machines and 2 AMADA Punch Machines.

State-of-the-art technology like this means we can process hundreds of tonnes of material weekly. This includes stainless steel, mild steel, or aluminium of differing grades, finishes, and thicknesses. We can work with lengths of up to 4 meters – perfect for EV charging infrastructure.

CNC Metal Forming

We use four press brake machines with lifting assistance with a maximum part length of 4 metres. We also have a Salvagnini automatic panel bender to double production compared to manual folding.

We also use two partially automated Haeger insertion machines and a Nutserting function – for pressing fixings.

Welding

JC Metalworks owns both robotic and manual TIG and MIG welding equipment. We can weld mild steel, stainless steel, and aluminium.

With 14 welding bays, each with extraction and two extended bays with lifting equipment, we can build many electric car charging stations and components quickly.

We also use spot-welding equipment for more cost-friendly projects.

After welding, our linishing team dress welds in a dedicated 40 sqm pressurised ventilation room. They then polish and brush the stainless steel EV charging equipment for a high-quality finish.

Powder Coating

We have invested in an in-house ITW Gema Powder Coating System. The equipment has:

- Six automatic coating guns,

- Ion phosphate pretreatment, and

- A two metres per minute track speed.

We can powder coat electric car charging stations made out of:

- Stainless steel,

- Mild steel, and

- Aluminium.

We can work with any colour, gloss level, ripple, texture and clear or tinted lacquers.

About Our Team and Our Facility

As well as having the highest quality equipment for manufacturing EV charging stations, our expert team has a state-of-the-art facility to work in.

Store and label

We may be able to store your charging stations at our own storage facility. We can agree to hold a certain number of electric vehicle charging stations to guarantee your stock levels. This is a perfect option for a company that sells charging stations, for example.

After we manufacture your EV charging stations, we can assemble, pack, label and despatch them as and when you need them.

Build & Dress

Our assembly team has more than 15,000 sq. ft of dedicated area to work with our manufactured metal and your non-metal parts. We have experience working with:

- Electrical components,

- Glass,

- Plastic,

- Joinery,

- Vinyl graphics, and

- Lighting.

We can source these extra materials for you or you can provide them yourself. We are incredibly flexible.

Receive & Acknowledge

Our team of account managers have a total of 60 years metal working experience between them. This helps them understand exactly what you need, so they can offer all the advice you need.

We have a separate team of estimators who accept briefs and repeat orders. They use specialist software to provide accurate, competitive quotes with a quick turnaround.

Distribute

All our goods go through one final check before being sent out. After a thorough inspection items are carefully packed before being handed to our logistic partners at Goods Out.

Why Choose JC Metalworks To Manufacture Your Electric Vehicle Charging Stations?

There are challenges and opportunities when designing and manufacturing EV charging stations. Our 35 years of experience means that we can meet these challenges head-on and harness the opportunities. Our advanced technology, innovative engineers, quality materials and manufacturing techniques mean we can provide a full service to perfection.

JC Metalworks is one of the UK’s largest fabricators and the leading British subcontract sheet metal fabricator. We can design and develop complete products and specific parts for stations that charge electric vehicles.

Our metal fabrication technology and equipment let us work with different material thicknesses – perfect for custom electric vehicle charging points.

Electric vehicle sales grew 2.7% compared to last year and will continue to grow once new petrol vehicle manufacture is banned in 2040.

We can build an entire EV charging infrastructure or manufacture a specific component. You can even send your components and once we’ve built the final pieces we will put it all together for you.

Get a Quote For Electric Vehicle Charging Station Manufacture

Whether you need us to manufacture charging stations for fully electric or semi-electric vehicles, our team can help. We’re excited to build a long-term relationship with your brand. Let’s work together to increase the vehicle charging stations market and keep EV drivers on the road.

Latest News

More Bespoke Solutions

Our precision metalwork expertise add value to a wide range of different industries.