Our Sheet Metal Fabrication Services

We offer a wide range of fabrication services to meet the unique needs of our clients. We work with a variety of materials, including aluminium, stainless steel and mild steel, and use cutting-edge technology to ensure the highest levels of precision and productivity in every project we undertake.Some of the metal fabrication services we provide include:

Aluminium Fabrication

We have the expertise and experience to handle any aluminium fabrication project, from simple to complex, with precision and attention to detail. Our team of skilled professionals use the latest technology to meet the unique requirements of each project. Whether you need custom aluminium parts, panels or frames, we are committed to providing exceptional service and superior products

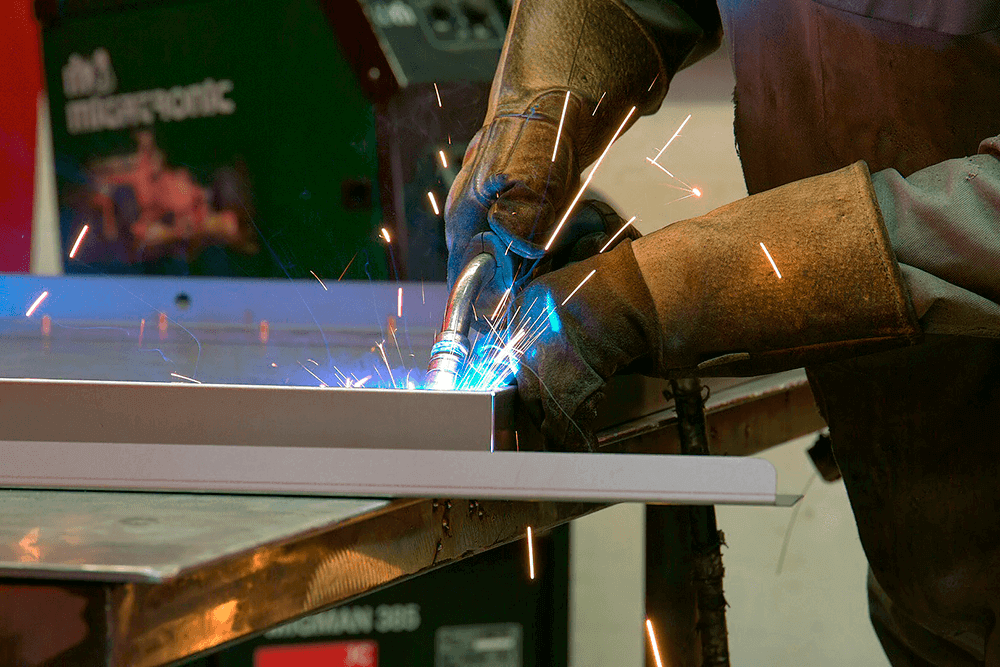

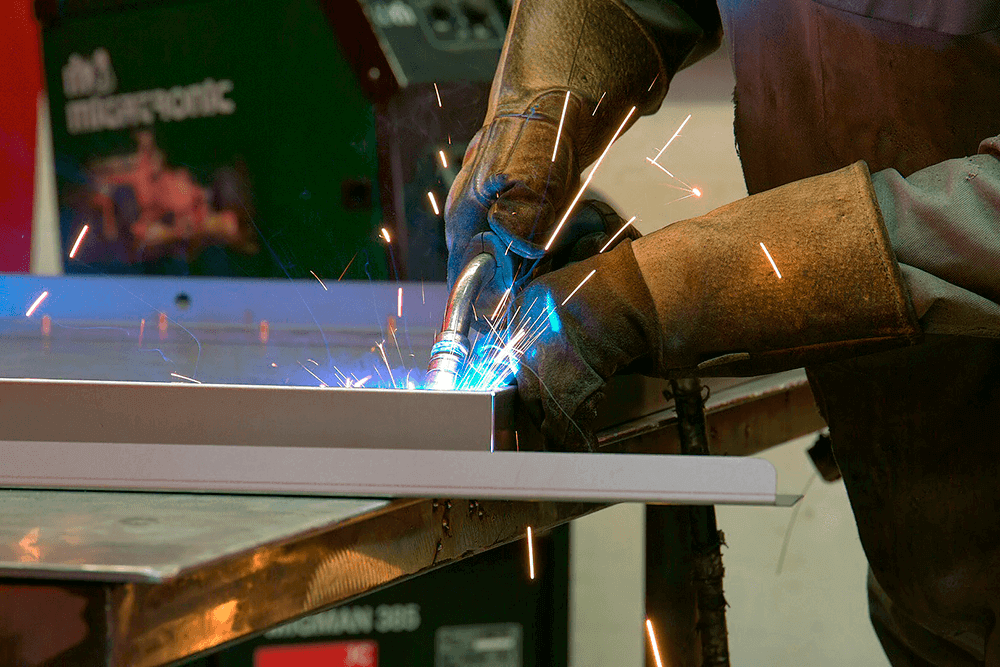

Stainless Steel Fabrication

Stainless steel is a stronger and more durable material than aluminium; it requires different fabrication methods such as welding and polishing, together with different finishing techniques. Therefore, it’s crucial to have specialised expertise in both types of fabrication to ensure high-quality and precise results.

From prototypes to the finished product

We designed our prototype development process to make sure our clients get exactly what they need. We can modify and adjust prototypes during the design process, before transferring them into bulk production.

Whether you need a few or a lot, we’ve got you covered.

Why choose JC Metalworks for your metal fabrication project?

Our 60,000-square-foot state-of-the-art manufacturing facility, quality equipment and experienced metal fabricators enable us to handle even the most complex sheet metal fabrication project. Whether you need a prototype or a large-scale production run, we have the ability and technology to deliver the results you need.

Here are a few reasons we’re the best choice for your fabrication project:

35 years of industry experience

We are proud to have over 35 years of experience in the metal fabrication industry. In that time, we have attained a deep understanding of the metal fabrication process, a key asset which set us apart from our competitors.

We have honed our skills and expertise through countless projects, ranging from small-scale prototypes to large-scale production runs. We have also worked with clients across a wide range of industries, providing us with a broad perspective on the needs and requirements of different sectors.

60,000-square-foot manufacturing facility

We are ideally situated in the centre of the UK, with excellent access to the transport network via motorway, rail and air freight.

We have invested in state-of-the-art equipment and assembled a team of skilled professionals with extensive industry experience. We have also focused on automation to achieve the highest possible standards of quality while offering faster turnaround.

Fabricating infrastructure and equipment

Our facilities include the latest technologies in metal fabrication such as fibre laser cutting machines, automatic panel bending machines, and TIG and MIG robotic welding equipment.

Our resources and equipment are key strengths of ours enabling us to deliver exceptional value and results. We remain committed to investing in the latest technologies to ensure that we always provide the highest quality products and services.

Our manufacturing processes are made possible through investment in the following:

- CNC Machining: Our CNC machining services allow us to produce high-quality complex parts.

- Fibre Laser Cutting and Punching: Our state-of-the-art laser cutting and punching equipment enables our skilled team to cut and create parts to your exact specifications.

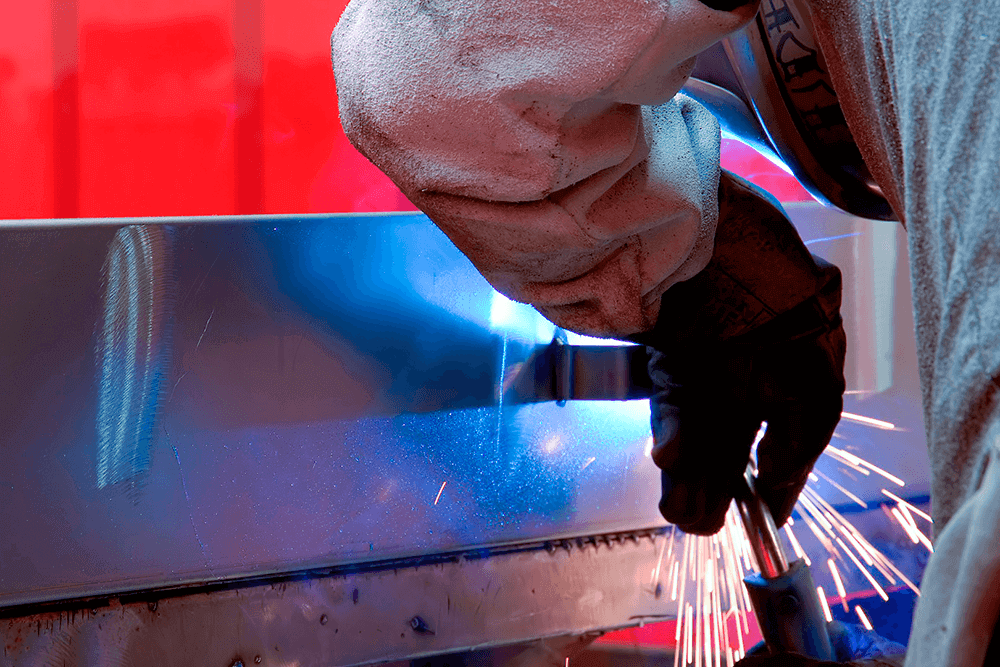

- Welding: Our skilled welders provide a wide range of services, including MIG, TIG, and spot welding.

- Powder coating: We can apply powder coat finishes in a wide range of colours and textures, to provide smooth and even finishes for your metal products with excellent corrosion, abrasion, and fade resistance.

- Product assembly: We provide assembly services to bring together all of your components into the final product.

Value engineering

Value engineering lies at the core of most of our sheet metal fabrication projects. Our clients greatly appreciate the suggestions and modifications made by us for their products.

One of the key roles of our engineers is to identify opportunities to optimise designs for manufacturability. They will work closely with you to modify designs that may be difficult or expensive to manufacture to help reduce costs and improve production efficiency.

Competitive prices

We strive to provide our products and services at competitive prices without ever compromising on quality or safety. Our estimation department uses the latest software to create accurate price quotes quickly to speed up the ordering process so you can get your finished product, fast.

Total quality management

Throughout our manufacturing processes, our team of skilled technicians and engineers carefully monitor all aspects of production to ensure our high standards are being met. This includes regular inspection and testing of materials, components and finished products, as well as identifying and addressing any non-conformance issues before they impact the final product.

We are ISO9001 and ISO14001 accredited.

Reducing our waste

Our engineers always aim to identify and eliminate waste in the manufacturing process. This can involve streamlining processes, reducing scrap and rework, and identifying opportunities for automation or improved equipment utilisation.

Reliable network of suppliers

JC Metalworks has a consistent and dependable supply of raw materials to ensure that we can meet customer demand and fulfil orders on time.

We have established strong relationships with our suppliers and have contingency plans in place for potential disruptions. A reliable supply chain is a key factor in maintaining a competitive edge in the industry and ensuring the long-term success of the relationships with our clients.

Top Tips for Metal Fabrication

Method of Fabrication

Make sure you are using the correct type of welding or fabrication for the strongest and most efficient outcome for the product.

Tools to succeed

Ensure the workspace is set up for the job in hand. Think about the size, equipment and tools needed.

Quality

The detailed engineered drawing needs to be fully understood to achieve the highest quality. Having the relevant checks in place mean you are always working within the plan.

Knowledge

Consider the material, thickness and finish. Using industry experience, make sure you are have selected the correct method. The handling of certain metals varies, something that needs to be factored in to every project.

Safety

Safe working procedures with the relevant PPE are vital. Keeping in constant communication within the team means projects run safely and smoothly.

Our sheet metal fabrication process

We understand that every project is unique and will work closely with you to ensure your needs are fully understood and met. From the initial consultation to project completion, you can expect open and transparent communication, and regular updates on project timelines, milestones, progress and any issues or challenges that arise along with our recommended solutions. We are always available to answer questions or provide guidance.

When we take on your project, we will begin with a thorough assessment of your needs and requirements, working closely with you to identify your specific goals, timelines and budget constraints to develop a detailed project plan.

Once the plan is in place, our project managers will liaise with our engineers, technicians and production staff to ensure that everything stays on track and on budget. This involves regular communication and coordination to ensure everyone works efficiently and effectively.

Our project managers will be your single point of contact and will be on hand to answer any questions or offer advice.

Projects we’ve worked on

Our metal fabricators have worked on numerous projects over the years. Some of our recent metal fabrication manufacturing projects have included:

- HVAC systems,

- Electrical enclosures,

- Metal cabinetry,

- Retail shop fittings,

- Lighting systems,

And more.

Latest News

Our Services

The complete end-to-end solution under one roof.