Why Choose Laser Cutting for Precise Metal Shapes?

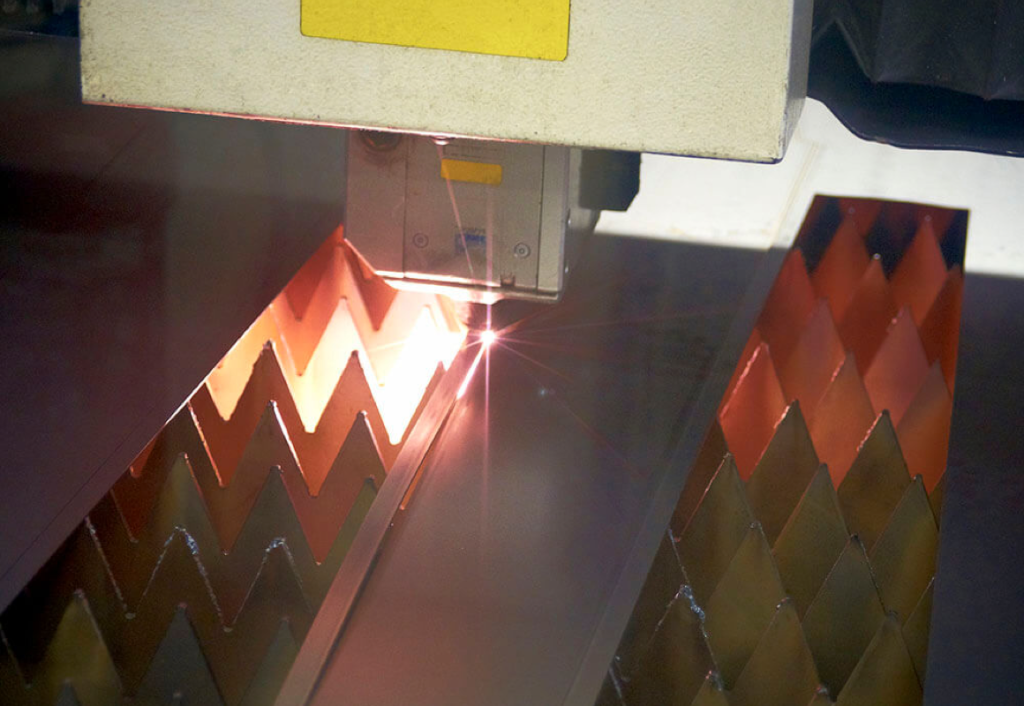

Precision sheet metal manufacturing requires a high level of detail and care when cutting sheet metal. There are effectively two options for metal cut to shape: sheet metal punching and metal laser cutting using a fibre laser.

Fibre laser technology relies on an optical fibre cable to guide its precision. This technology combines low maintenance and operational costs with excellent electrical efficiency and precision making it a fantastic choice for sheet metal manufacture.

Laser cutting also makes use of a highly focused beam of light for metal cooking. This technique is more accurate than plasma cutting, making it an ideal solution for detailed metalwork.

Our metal cutting machines can handle a variety of tasks including aluminium laser cutting and laser cutting stainless steel, ensuring that we meet the exact specifications of a product shape set out by our client.

Our Laser Cutters

Our industrial metal laser cutters use pinpoint accuracy to cut raw metal into intricate and often varied shapes. We’re often asked about material thickness. We can work with a range of thicknesses from paper-thin metals through to cutting thick materials like 20mm steel.

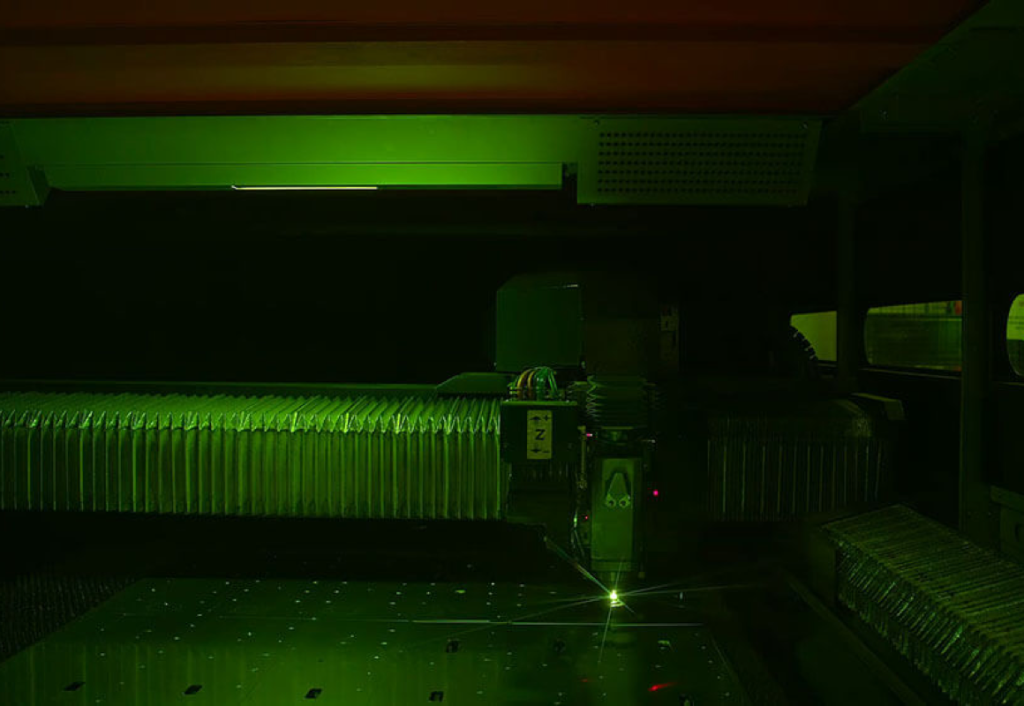

AMADA VENTIS-3015AJ Fibre Laser

The VENTIS-3015AJ is an innovative fibre laser processing machine that uses groundbreaking technology for sheet metal cutting.

Amada FOL3015 AJ Fibre Laser Cutter

The Amada FOL3015 AJ fibre laser cutter has the technology to allow for extremely fast and high-quality accurate laser cutting of sheet metal, whilst being reliably automated, cutting down both operation time and costs.

Fast & Effective

The good news is that minimum set-up is involved when laser cutting metal. This makes producing laser cut stainless steel or aluminium metal products, parts or components a quick process. Drawings containing the cutting lines are used to guide the process, helping lasers work at speed.

This metal cutting process usually takes place before moving onto the metal forming and fabrication stages, saving on overall manufacturing time and cost.

What Can Laser Cutters Produce?

Typical examples of products created using laser-cut metal include the manufacture of point of sale units and retail fixtures, HVAC systems, self-service kiosks, electrical enclosures and machine guarding, along with light parts and lighting systems.

Custom cut metal shapes can be created to your exact specifications. We’ve created all sorts of shapes out of metal, so get in touch to discuss your requirements.

Why Choose JC Metalworks?

We are one of the UK’s leading custom manufacturers and suppliers of high volume, bespoke sheet metal laser cutting services.

Having worked in the metal manufacturing and sheet metal laser cutting industry for over 30 years there isn’t much that we haven’t seen or done! Do get in touch to discuss your requirements.

Metal Plates

With over 30 years’ experience, we provide unparalleled levels of quality, durability and expertise in the production of metal base plates, industrial fan plates and post base plates, from materials including steel, stainless steel aluminium, and zinc.

Metal Laser Cutting Stainless

Steel & Aluminium

Custom metal laser cutting is a key component in the precision metal manufacturing process here at JC Metalworks. It perfectly complements our metalwork design and precision engineering service, CNC metal punching, forming, welding and fabrication, metal finishing and product assembly services.

Our commitment to further inward investment and having our manufacturing facilities on-site ensures our place as leaders in the UK sheet metal cutting and metal fabrication industry.

We work with our clients to create designs for the production of precisely shaped metal parts and components. We are capable of processing hundreds of tonnes of material each week at a maximum length of four metres. We work with stainless steel, mild steel and aluminium at numerous grades, finishes and thicknesses using our state of the art Amada fibre laser cutters. From here, the metal is ready for further precision manufacturing processes.

Whether it be copper, brass, steel sheet metal or aluminium, we offer an accurate and cost-effective solution for a wide variety of applications.

Please don’t hesitate to get in touch with us at our metal works headquarters in Loughborough, Leicestershire. Find out how we can use our high volume, metal cutting expertise to create your flat, shaped, metal product or component today. Use our contact form or call us on 01509 233280.

Knowhow

What is a Laser Cutter?

A laser cutter is a machine that uses a high power laser to cut detailed metal shapes. Its main advantages include precision and accuracy. Fibre laser technology is also energy efficient, helping to reduce carbon emissions. As the process is faster and uses less energy it’s much more efficient and sustainable.

Latest News

Our Services

The complete end-to-end solution under one roof.