Stainless steel fabrication solutions

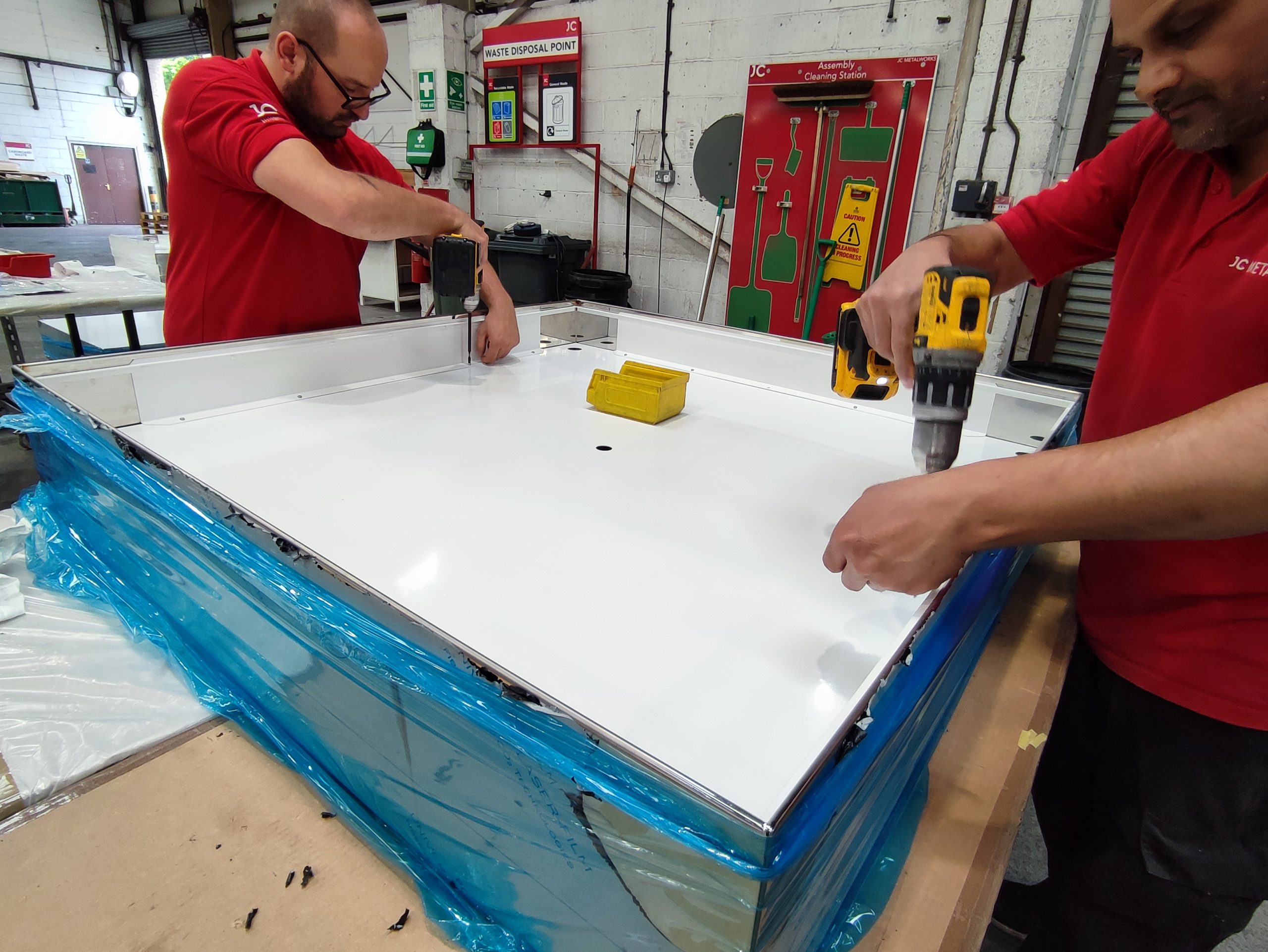

Our stainless steel fabrication service is one option from the full-service metalwork solutions we offer. In our fabrication workshop, we take different materials that have been through our quality checks, design, cutting and forming processes and weld them together, before linishing and dressing in readiness for finishing with powder coating.

The high level of skill and control that comes from our experienced team ensures that we deliver high-quality parts and components through to fully finished products every time.

We are continually investing in our workshops and tooling to ensure we have an optimised environment to carry out our steelwork. The dedicated fabrication workshop within our precision manufacturing facility provides ideal operational conditions, ensuring the finest products are ready for the next stage of their manufacturing journey, on time and to exceptional standards.

Types of steel used in metal fabrication

Both mild steel and stainless steel are raw materials that can be used for the fabrication of components or products. If you are not sure which is the best material for your application, our experienced team can advise.

Pros and cons of mild steel

Mild steel, or low-carbon steel, is a popular choice for a variety of industrial projects. Mild steel lends itself well to machining and welding, as it is ductile, malleable and transfers heat easily.

It is more affordable than some other materials but is not suitable for harsh or damp environments due to its susceptibility to corrosion.

Pros and cons of stainless steel

Stainless steel offers corrosion resistance, as well as durability, high tensile strength, temperature resistance and low maintenance. Although a harder material than mild steel, it is easy to form and fabricate and provides an attractive appearance on products and components.

Our fabrication process is all taken care of in-house by our experienced and skilled team.

Which steel is best for fabrication?

Both types of steel are great materials for metal fabrication. Which one is ‘best’ will depend on your project and requirements.

JC Metalworks undertakes all types of projects for bulk production, for many different applications and industries. For each specific project, our experienced team will identify the best steel based on many factors including the industry, environment, application and fabrication requirements and discuss this with you before undertaking the work.

Prefer aluminium fabrication?

We also specialise in aluminium fabrication.

Why choose JC Metalworks for your steel fabrication project?

We are an industry-leading sheet metal fabricator, specialising in steelwork and providing a complete end-to-end service right here at our manufacturing facility. Over the years, we have built a reputation as one of the leading exponents in the UK welding & fabrication industry.

Here are some of the reasons customers choose us to manufacture steel products to their exact specifications:

Providing high-quality stainless steel fabrication services for more than 35 years

With over 35 years of experience in the metal fabrication industry, we provide an end-to-end service, from design and project management, through to cutting, forming, fabrication, finishing, assembly and despatch.

Our team includes some of the most talented and knowledgeable professionals in the industry, who bring a wealth of expertise and creativity to every project they undertake.

60,000-square-foot metal fabrication facility

All of our fabricating is done on-site, right here in the heart of the East Midlands.

Using lean manufacturing and 5S techniques, we not only ensure the best end products but also faster turnaround and cost-efficiencies. We achieve this by continually investing in our premises and in the latest machinery and tooling.

Strong focus on quality

With stringent checks in place, we have effective quality management at all stages. Not only does this mean that you receive the very best end product, but that time is saved by catching potential issues before they morph into costly problems.

It also means that every single product we build within a project is exactly the same as the next, leaving you with nothing to worry about.

Experienced in numerous industries

We work across many industries, including:

- Retail,

- Industrial,

- Scientific,

- Security,

- Electrical and

- HVAC.

So you can trust that any recommendations we make regarding the design and manufacture of your product are based on deep experience. By using the knowledge gained from our extensive steel fabrication history, we can help you save costs and create the best product possible.

Subcontract our fabrication services at a competitive price

We provide subcontracted fabrication as a specialist service. When you take out a contract with us, you can expect:

Expertise: We have many years of experience in stainless steel fabrication, and our team of experts has the knowledge and skills required to handle even the most complex fabrication projects. We have a thorough understanding of the material properties and fabrication techniques necessary to produce high-quality stainless steel products and parts.

Customization: We take a customised approach to fabrication. Your project manager will work closely with you to understand your requirements and provide solutions that meet your needs.

Quality: We have a reputation for delivering high-quality stainless steel products that meet or exceed industry standards. We have stringent quality control measures in place to ensure that each product is carefully inspected and tested before delivery.

Efficiency: Our streamlined fabrication process allows us to complete projects quickly and efficiently, without sacrificing quality. We have the necessary equipment and resources to handle large volumes of fabrication work, while still maintaining a high level of precision and attention to detail.

Customer Service: We value our customers and provide exceptional customer service throughout the fabrication process. We are responsive to client needs, and our team of experts is always available to answer any queries and provide guidance.

Overall, JC Metalworks is a reliable and trusted subcontractor for stainless steel fabrication.

Our stainless steel fabrication process

From concept to delivery, we have a complete end-to-end solution under one roof. We strive to give our customers the best possible experience, with unparalleled industry insight and expertise.

When you choose us you’ll be assigned a project manager, who will stay with you through the entirety of the project – whether that’s a one-off bulk order or a complete range to be delivered every month.

Our process begins in the design and engineering department, where our expert engineers will bring your idea to life through design, development and prototyping.

Manufacturing comes next, first into laser cutting and punching, then forming, before heading into the metal fabrication area. After this, it’s on to finishing, assembly and packing, before your products are despatched directly to you or held in storage.

Previous stainless steel fabrication projects

We have completed a variety of different projects over the years. From pedestals with LED lighting for the retail industry and vents for prisons to digital kiosks, take a look at our case studies for a taste of our capabilities

Knowhow

What Metals are Used in Metal Fabrication?

Metal fabrication is the process whereby individual metal parts are welded together, linished, and dressed, to make them ready for finishing, either with chrome plating or powder coating.

Latest News

Our Services

The complete end-to-end solution under one roof.