Metal Manufacturing Services

From concept to delivery, we have the complete end-to-end solution under one roof. We strive to give our customers the best possible experience, with unparalleled industry insight and unbeaten quality. Our capabilities are limitless. From the initial metal product design to CNC punching and metal finishing, we do the whole process. And because we care about quality and communication, we offer full project management for your metalwork to ensure you’re updated every step of the way.

Bespoke metal fabrication

Our metal fabrication services include cutting, bending, welding, finishing and assembly. In addition, we offer design, consultation and project management expertise to ensure that the entire process is seamless and highly cost-effective.

Metal plate supplier

Need high-quality metal plates? We are a leading metal plate supplier and fabricator offering a vast selection of steel and aluminium. We have a lot of capability and availability. We can offer a range of thicknesses and you can order in bulk.

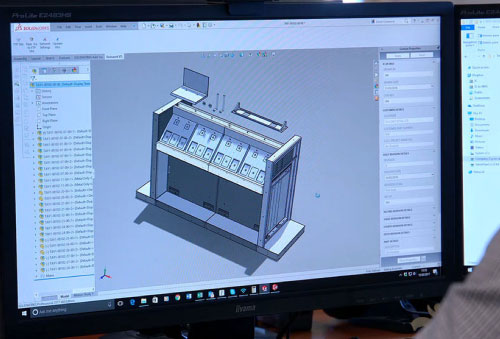

Design & Engineering

JC Metalworks in-house team of expert design engineers have 35 years of experience and metalwork knowledge. This means our team adds real value to every single project we work on including design, development and prototyping. It’s the heart and soul of every project we deliver for our customers.

Project Management

No matter how complex your project is, our experienced project management team offer a single point of contact service and expert advice from concept to delivery. With best in class communications, scheduling and regular project updates – you’ll have what you need when you need it.

METALWORK PROJECT MANAGEMENT

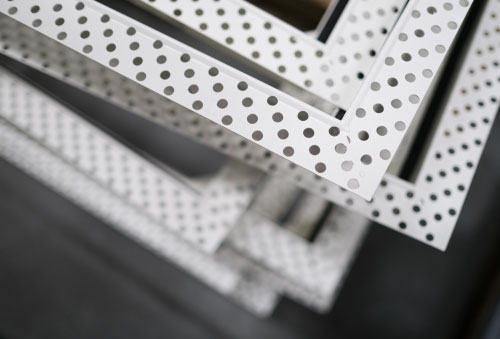

Laser & Punching

From our state of the art facility we offer fast turnaround, high volume laser profiling, cutting and punching. Whether it’s stainless steel or aluminium, we can work with thicknesses up to 20mm. That’s why we’re one of the UK’s leading providers.

CNC PUNCHING

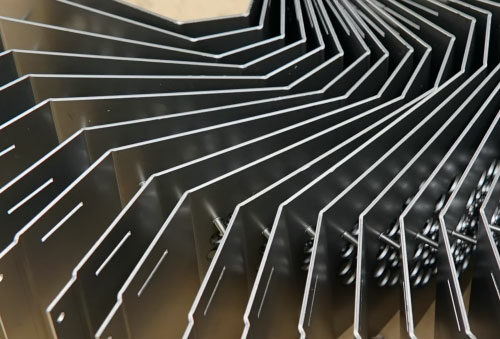

Forming

We are one of the UK’s leading suppliers of high volume, custom metal forming. We bend, shape and form metal sheet, tube or wire, for the production of precision fabricated and manufactured steel, aluminium, copper or brass components or finished products.

METAL FORMING

Welding

With our huge wealth of experience across MIG welding, TIG welding and spot welding, we are able to manage high volumes of aluminium and stainless steel fabrication. This is key to our manufacture of large volumes of both component parts and finished products.

METAL FABRICATION AND WELDING

Finishing

We have one of the UK’s most flexible and productive metal finishing lines – whether it be metal coating, lacquering, metal plating, metal polishing or printing; metal finishing forms an invaluable part of our high volume, precision manufacturing offering.

METAL FINISHING

Assembly & Pack

Final product assembly has become an important part of our concept to delivery offering. Through our 10,000 sq ft dedicated assembly space we are able to accommodate even the most complex assemblies, including full packing and palletising. That’s why leading brands use our end to end service.

PRODUCT ASSEMBLY & PACKING

Storage & Despatch

We manage the storage and despatch for many leading brands, and are able to arrange bespoke packaging around your needs and organise all necessary logistics. This is an integral part of our full concept-to-delivery service, so every care is taken to ensure the integrity of the product.

STORAGE & DESPATCH

Why JC Metalworks for metal manufacturing?

Having problems with your current supplier? Is the quality slipping, or do you need capacity for bigger orders with a faster turnaround? We pride ourselves on producing exceptional quality fabrication services, even if your order is much bigger.

We’ve been a trusted partner in precision metalwork and bespoke fabrication for decades – so our experience, innovation, technical knowledge and quality is unparalleled.

30 years’ experience

End-to-end service

Engineer or Reverse Engineer

Technical Experts

What industries do we manufacture sheet metal?

We can work with almost any industry, including the below.

- Digital signage

- Construction

- Transport

- Scientific

- Power

- Construction

- Medical

- Telecommunications

- Food processing

- Defense

- Security

- Retail

Sustainability in sheet metal fabrication services

We are dedicated to sustainability and reducing our environmental impact through energy efficient measures. We prioritise implementing energy efficient practices through our operations to minimise our carbon footprint.

By leveraging advanced technologies and optimising our manufacturing processes, we strive to conserve energy and reduce waste. Our commitment to energy efficiency benefits the environment and allows us to provide you with sustainable solutions that align with their eco-conscious goals.