Precision Engineering UK Metalwork Design Projects

What can our specialist metalwork design team do?

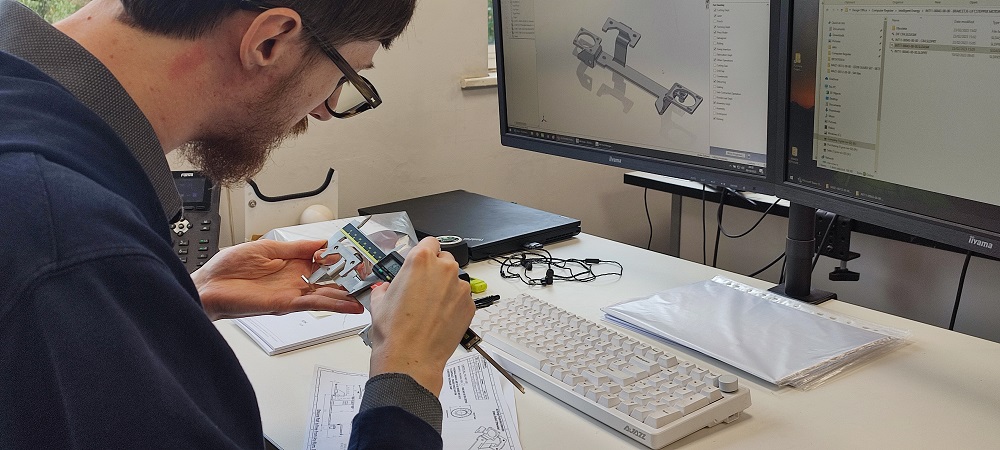

Through the use of skilled, modern, precision engineering design techniques, our specialist in-house design engineers take a product design concept or idea from a client and turn them into fully specified and engineered product design drawings ready for their precision metal work manufacture and fabrication.

Here at our precision engineering company – JC Metalworks, Lean Manufacturing techniques are applied to greatly reduce the time taken during the process of manufacturing a product.

What sectors do we offer metal work design for?

From retail kiosks to vending fabrication, we can work with almost anything!

Using our many years of retail, industrial and commercial metalwork design and precision engineering experience, our design engineers are extremely creative during the product design engineering process. They always look for opportunities to deliver added value and cost savings for our clients.

Metalwork design specialists with a process

Our design engineering project managers and skilled craftsmen work as a team to make the most of the modern and sophisticated precision engineering machinery and equipment within our facility for the benefit of each and every client we work with. For every metalwork design brief we receive, the end product will be thoroughly assessed to understand where we can improve quality, whilst reducing lead times and costs for our clients.

For our metalwork design company, the design engineering and manufacture of a metal part or product is focused around quality and customer satisfaction. No product starts its manufacture until our design engineering team are certain it meets the specifications required by our client.

For our Company, the manufacturing of a metal product is focused around quality and customer satisfaction. No product starts manufacture until our engineers are certain it meets the specifications required by our client.

Typical examples of projects managed by us include:

- point of sale stands

- display units

- retail fixtures and fittings

- HVAC systems

- electrical enclosures and lighting systems.

Having worked in the metal manufacturing industry for over 30 years, there isn’t much that we haven’t seen or done so do get in touch to discuss which of our metalworking services, including project management, that your project can benefit from.

For more information, see our full range of metal manufacturing services

Top Tips for Metalwork Design & Precision Engineering

Define the product

Understand the product vision to help keep the focus but allow room for ideas to develop.

Product research

Recognise both the competition and the audience. Early extensive research will save resources further along the design process.

Ideation

Sketching, Modelling, CAD work. Use a range of methods to explore different ideas that will challenge and confirm assumptions.

Prototyping

Every decision that is designed at this point will impact the final product. Manufacturing cost, user experience, transport and even disposal - refining the design at this stage is critical.

Design for the real world

The design process is not linear. Be flexible and adapt to the project, moving back and forth as the team learns more about the problems being solved.

Metalwork Product Design & Modern Precision Engineering Company

An intimate knowledge and experience of our precision engineering equipment and manufacturing processes allows our industrial, commercial or retail metalwork design services and precision engineering team to fully assess where savings can be made during each product’s manufacture: from laser cutting, CNC metal punching, sheet metal forming, metal fabrication through to powder coating, packaging and assembly.

Modern precision engineering techniques are a key component in the metal manufacturing process here at our metalwork design company. Whether the solution includes aluminium, copper, brass or steel, we offer design, engineering and manufacturing for components or finished metal products that are practical and cost effective solutions for a wide variety of applications.

Our commitment to further inward investment and having our design and engineering facilities on-site in the UK ensures our place as leaders in the UK precision engineering, metal fabrication and product manufacturing industry.

Latest News

Our Services

The complete end-to-end solution under one roof.