Metal bending, a fundamental process in modern manufacturing, transforms flat metal sheets into a wide variety of functional shapes. From structural components in construction to intricate parts in electronics, metal bending plays a vital role in countless industries.

In this article, we’ll explore the different types of metal bending techniques, the most commonly used metals, and the benefits this process brings to fabrication projects.

What is Metal Bending?

Metal bending refers to the deformation of metal, a technique that forces metal sheets, tubes and wire into a desired angle or curvature without causing it to crack or break. This process involves using specialised tools like press brakes, dies, and rollers to achieve accurate bends. Precision is the key to successful metal bending, as even small deviations can impact a component’s structural integrity or fit.

Common Metals Used for Bending

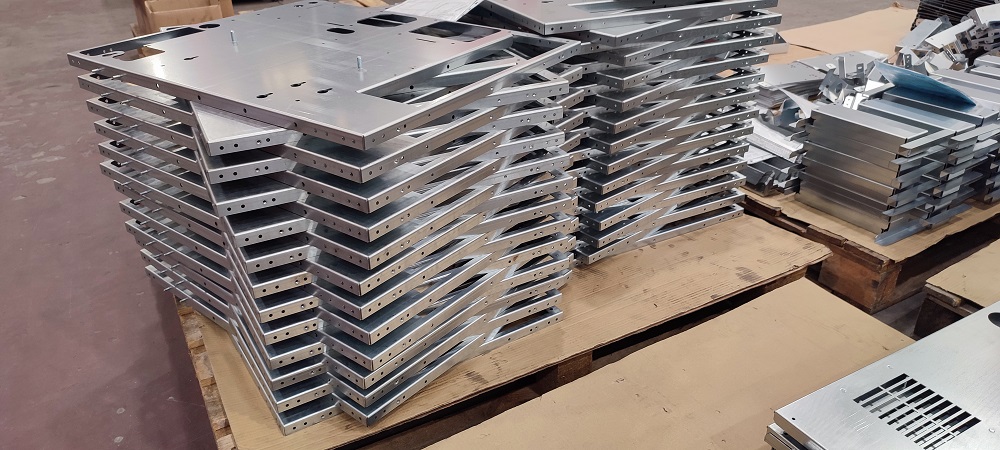

Different metals respond to bending in unique ways, making material selection an important factor in fabrication projects. Commonly used metals include aluminium, stainless steel, and carbon steel.

Aluminium is lightweight and highly malleable, making it ideal for applications where weight reduction is important, such as in electrical enclosures and retail displays. Its corrosion resistance also makes it suitable for outdoor signage and structures.

Stainless steel is known for its strength and durability. It can be bent into precise shapes while maintaining its integrity, making it a common choice in industries with metal lockers, point-of-sale (POS) equipment, and office furniture manufacturing.

Carbon steel is more malleable than stainless steel and is used to create strong structural components. Its lower cost makes it a popular choice for construction projects.

Types of Metal Bending Techniques

Various techniques bend metal, depending on the required precision, material, and final application of the products created. Below are some of the most commonly used techniques:

- Air Bending: This technique uses less force, as the punch does not fully press the metal into the die. This allows for a variety of bend angles but can result in less accuracy than other methods.

- Bottom Bending: This method, also called bottoming, involves the punch fully pressing the metal into the die. It provides more accurate bends and is often used when precision is critical.

- Coining: In coining, the metal is compressed with high force between the punch and die, which creates an exact, permanent bend. It is ideal for projects requiring highly accurate, repeatable bends.

- Roll Bending: One of the most common sheet metal bending processes involves running metal between rollers to produce large-radius bends, which are often used in the construction of cylindrical shapes like tubes and pipes.

- Rotary Draw Bending: This is commonly used for bending pipes and tubes with consistent radii, and it is often found in applications like handrails or exhaust pipes.

- Wipe Bending: The bent sheet metal parts are held in place while a punch wipes across it, creating a sharp angle bend. This is a popular method in sheet metal fabrication for creating tight bends.

Advantages of Metal Bending

There are numerous benefits to using metal bending in fabrication, especially when working with complex or large-scale projects. Whether using CNC bending machines, rotary bending or one of the other bending methods, metal formation has the following advantages:

- Durability: Metals retain their strength after being bent, ensuring the product’s longevity.

- Versatility: Metal bending is ideal for creating a wide variety of shapes, both simple and intricate.

- Cost Efficiency: Metal bending reduces the need for additional components and welding, simplifying the assembly process and cutting costs.

- Accuracy: Modern metal bending techniques offer high precision, even for complex designs. This results in more reliable parts that fit together with greater ease.

Challenges and Considerations in Metal Bending

While highly effective, metal bending can present challenges that need careful management to ensure the best results. One common issue is springback, where metals tend to return slightly to their original shape after bending. Compensation measures are necessary to address this during the bending process.

Material thickness is another challenge, as thicker metals require more force and specialised equipment to bend properly without causing damage. Additionally, selecting the correct bend radius is crucial. If the radius is too sharp, it can cause the metal to crack, quickly turning an angular shape into a failed project. This is why it’s essential to consider the material’s properties when determining the appropriate bend allowance for each project.

Need Metal Bending Services?

Metal bending is an indispensable technique in modern manufacturing, enabling the creation of durable, versatile, and highly accurate components. From construction and automotive to aerospace and design, the applications of metal bending are virtually limitless. By understanding the different bending techniques and the properties of various metals, manufacturers can produce high-quality parts that meet the specific demands of each project.

At JC Metalworks, we specialise in precision metal fabrication, offering a range of bending services that are tailored to your exact requirements. Whether you need a one-off prototype or high-volume production, our team is here to deliver the highest standards of quality and reliability.

Contact us at 01509 233280 to discuss your requirements and how we can help.