Known for its speedy set-up times, fast cycle times and rapid offline programming.

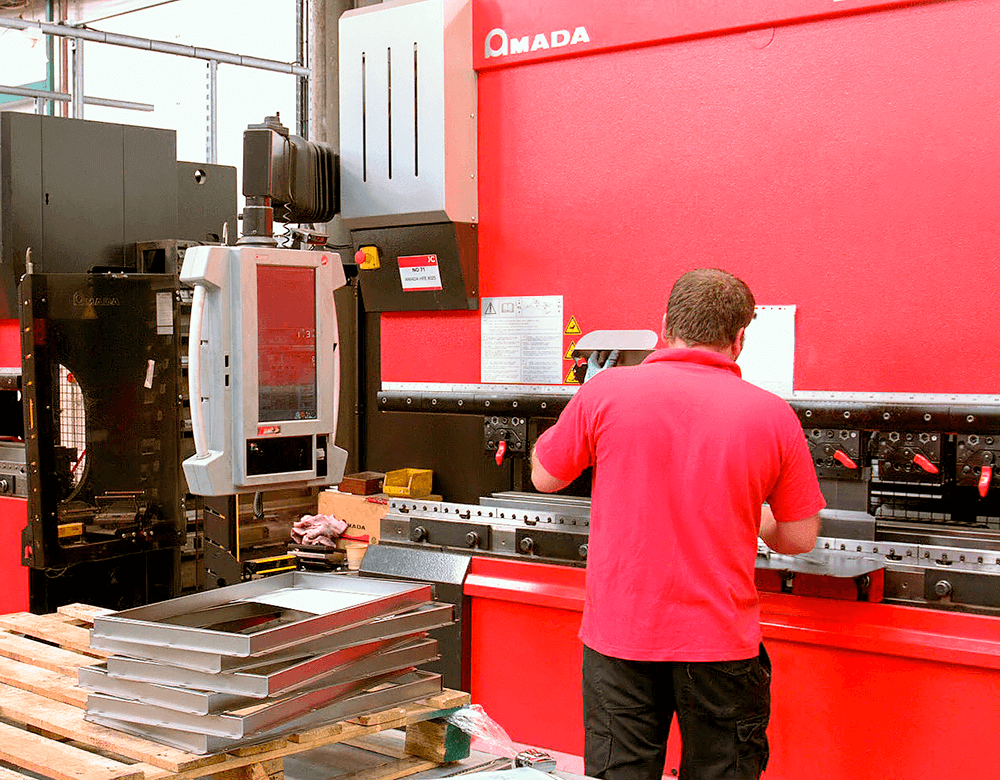

Using state-of-the-art CNC press brakes and automated sheet metal forming tools, we deliver efficient, high-quality sheet metal forming, pressing and panel bending services. Working with steel and aluminium, our team turn client projects around quickly and to an outstanding standard.

Sheet metal forming, also known as panel bending, involves a combination of processes to stretch or bend metal into different intricate shapes without sacrificing the strength and durability of the metal.

By modifying the geometry of the steel or aluminium, we are able to bend the material into a variety of different shapes using a smaller amount of material than would be required in other processes. Doing this allows us to reduce metal waste and pass savings directly to our clients.

Sheet metal bending is the process of shaping flat metal sheets by applying force along a straight axis to create precise angles and folds. It’s done using press brakes or folding machines to produce components like panels, brackets, and enclosures. Unlike sheet metal forming, which can involve stretching, drawing, or rolling to reshape metal, bending specifically focuses on creating controlled angles without changing the sheet’s thickness.

This process is used in almost all manufacturing industries. The aerospace, automotive industry, construction, electronics and energy sectors often make regular use of panel bending, however, any company that turns raw materials into structures can likely benefit from the sheet metal forming process.

Known for its speedy set-up times, fast cycle times and rapid offline programming.

With bend lengths of 3m and swift changeover tooling.

At JC Metalworks, we work with aluminium, mild steel and stainless steel sheet, using lean manufacturing and 5s techniques (sort, set in order, shine, standardise, sustain), to ensure top quality, fast turn around and cost-efficiencies for our clients.

We are one of the UK’s leading custom manufacturers and suppliers of high volume, bespoke forming services. We can manufacture large quantities to order with high precision, producing the final form to your requirements.

Having worked in the sheet metal manufacturing industry for over 30 years there isn’t much that we haven’t seen or done with sheet metals.

The metal shaping tools we utilise are unparalleled when it comes to reliability and repeatability, allowing us to turn projects around efficiently within compressed timeframes.

If you require paper-thin panel bending, we can offer high-quality parts or components through to a fully finished product each and every time.

We are continually investing in equipment to ensure we remain not only at the cutting edge of our market but remain the Midland’s leading custom manufacturer and supplier of bespoke metal forming.

Through a selection of trusted and approved partners, we can source wire bending and tube forming services on your behalf. Please get in touch with details about your project and we can discuss how we can help. We can competitively source:

Typical CNC wire formed products and components that we source from trusted third parties in high volumes include display racks, d-arms, curved headers, chair frames, furniture frames, seat frames, support legs and much more.

This is an umbrella term for the metal forming processes used when steel pipes or tubes are permanently bent or formed. This is another service that we can source on your behalf from our trusted partners.

We only work with partners that will further enhance the type of products we are able to manufacture, putting the quality of our products and our client’s requirements at the forefront at all times.

Our knowledgeable sheet metal folders will manage your projects to ensure all component manufacturing seamlessly fits into an agreed production schedule. We also offer metal finishing so you can get the surface finish you require.

We are grateful to Yamazaki Mazak for providing JC Metalworks apprentices Frances Miller and Josh Dalton with the opportunity to spend two days at their UK facility. Dive into the firsthand account of Frances Miller as she recounts her transformative…

The time required depends on the complexity, size, and material of the component. At JC Metalworks, our automated CNC press brakes and efficient workflow allow us to deliver even large or intricate projects on tight schedules without compromising quality.

Absolutely. CNC press brakes and automated forming tools ensure that every bend and panel is made to exact specifications, reducing errors, improving repeatability, and speeding up production.

Yes, we provide a range of finishing options, including mirror finishing, buffing and powder coating, to ensure the surface finish meets both aesthetic and functional requirements.

We can work with a wide range of sheet sizes, from small panels to large-scale sheets, ensuring we can accommodate both small components and large structural parts.

Think we could help you? Get in touch with our expert team to discuss your exact requirements.

Yes, formed panels can be welded, drilled, assembled, or coated as part of a larger manufacturing process, giving flexibility for complex projects.

By optimising material usage and using precise CNC programming, we minimise scrap and excess cuts, which not only saves costs but also supports sustainable manufacturing practices.