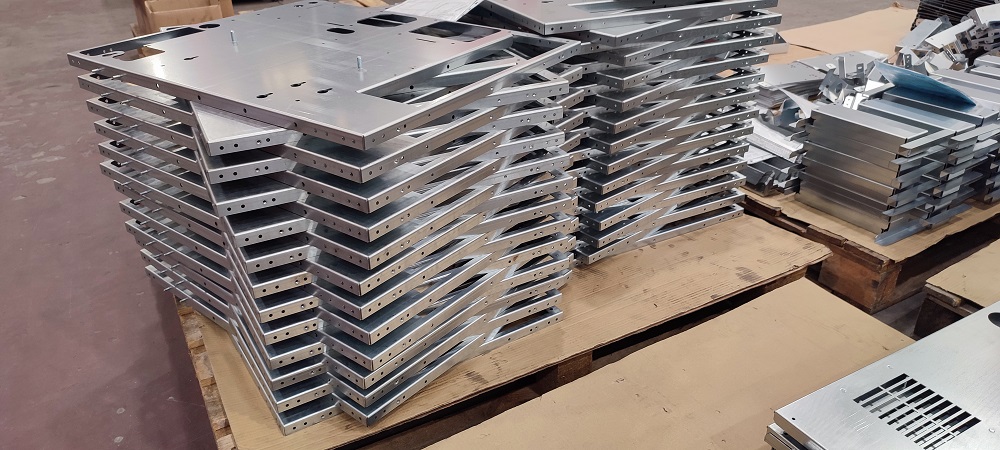

A dedicated resource and processes for checking quality standards

Our Quality and Assurance team carries out comprehensive checks at almost every point in the manufacturing process. These inspections ensure that we produce the most high-quality sheet metal product possible whilst meeting our clients’ exact specifications.

During the powder coating stage, we test the thickness of the coating. The viscosity of the coating is important to ensuring an even coat and optimal protection of the sheet metal product. We also conduct a daily adhesion test which ensures that the powder coating will effectively stick to every sheet metal product we manufacture – and, that the coating will last for a long time.

Our team of experts also conducts first-off checks for the first item of every run that is produced. This thorough examination ensures that the sheet metal product fits the clients’ exact specifications whilst testing it to ensure a high quality overall.

Environmental Responsibility

As a lean manufacturer, dedicated to safe and efficient working practices, taking care of the environment makes sound business sense. Automation and CAD/CAM systems help reduce waste and what little remains is recycled.

Packaging is reduced to the minimum whilst energy efficiency is a key criterion against which equipment and processes are evaluated. Careful management and reduced waste allows the business to keep costs low. For example, the new powder coating plant collects and recycles unused powder, reducing raw material use by 50%.