CNC punching is a highly efficient and precise method in modern metal fabrication. Using computer-controlled machinery, CNC punching delivers superior accuracy and speed, enabling manufacturers to create complex shapes and holes in sheet metal without manual processes. This metal punching process has revolutionised industries like automotive, construction, and electronics, where perfect precision is needed, and efficiency is a huge competitive advantage.

In this blog, we explore what CNC punching is, how it works, its benefits, and its various applications across different industries.

What is CNC Punching?

CNC (Computer Numerical Control) punching is a metal fabrication process in which a computer guides a punch press to create holes, slots, and intricate designs in sheet metal.

The CNC system follows precise programming instructions to control the movement of the punch and die, ensuring high accuracy and repeatability. Unlike manual punching, CNC punching allows for the automation of complex tasks, significantly improving both speed and consistency in production.

This process is widely used to create parts for various industries, thanks to its versatility and ability to handle different materials, from thin aluminium to tougher metals like stainless steel.

How Does CNC Punching Work?

CNC punching involves several steps, all controlled by computerised technology to achieve the desired shape and pattern:

- Design Input: The first step is programming the desired design into the CNC punching machine. This is done through specialised software where engineers input the shapes, hole sizes, and patterns required for the project.

- Positioning the Sheet Metal: The sheet metal is placed onto the machine’s worktable, where clamps secure it in place. The CNC system then moves the sheet metal beneath the machine’s punching ram according to the programmed design.

- Punching Process: The punch tool, fitted with a specific shape or size, is pressed into the sheet metal to create a hole or cut. Depending on the size and shape of the cut required, different punch tools are used, including round, square, and custom designs.

- Automation and Precision: The CNC system controls each punch’s force, positioning, and timing. This results in an extremely precise and efficient process, producing consistent parts with minimal waste.

Materials Commonly Used in CNC Punching

CNC punching machines are compatible with various metals, some of the most common of which are:

- Aluminium

- Stainless Steel

- Mild Steel

- Zintec

Key Benefits of CNC Punching

CNC machines offer a range of advantages that make it a preferred fabrication method across industries. Our client’s favourite benefits include:

- Precision and tight tolerances: CNC technology ensures extremely accurate punches, even for really intricate designs. This is particularly important in industries where parts must fit together seamlessly every time.

- Efficiency: CNC punching is much faster than manual punch presses, as the automation allows for continuous production with minimal human intervention. This reduces labour costs and speeds up the manufacturing process, allowing for quicker turnaround times.

- Versatility: CNC punching’s flexibility allows manufacturers to create a wide range of shapes and sizes, from simple perforations to complex patterns. It’s a highly adaptable process that can handle different materials and thicknesses, making it ideal for customised projects.

- Cost and energy-effective: CNC punching offers significant cost savings by producing large volumes of parts with minimal material waste. The process’s precision also reduces the need for post-processing, further cutting production costs.

Applications of CNC Punching

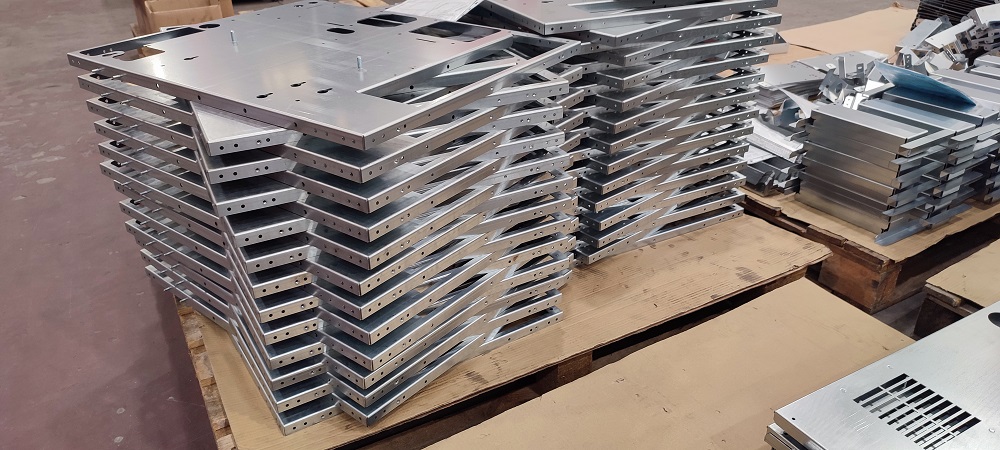

CNC punching is used across various industries, allowing manufacturers to produce high-quality, custom parts quickly and efficiently. CNC punching is ideal for producing perforated panels, ventilation slots, precise louvres, and other custom designs that are crucial for maintaining proper airflow and functionality for electrical enclosures.

Structural components like metal brackets, beams, and fittings are often manufactured through CNC punching. The process’s versatility allows custom parts to be customised to a project’s exact specifications. The aerospace industry also tends to rely heavily on CNC punching to produce lightweight, precision-engineered parts for aircraft. Given the strict safety standards in this industry, the accuracy of CNC punching is critical to ensuring the reliability of each component.

CNC Punching vs Other Sheet Metal Punching Processes

CNC punching’s precision, efficiency, and versatility set it apart from other metal punching processes. Unlike traditional punching methods and metal laser cutting, CNC punching uses computer-controlled machines to perform highly accurate and repeatable punches, which allows for intricate designs and complex patterns with minimal error. This level of precision is crucial for industries that require exact specifications.

Additionally, CNC punching can handle a variety of metals and material thicknesses, making it more adaptable than conventional methods. Its ability to combine multiple processes—such as punching, forming, and perforating—into one seamless operation improves overall efficiency, reducing production time and costs. The integration of software programming enables quick adjustments and customisations, making it ideal for both small prototype runs and high-volume production.

Moreover, CNC punching offers the best repeatability, ensuring that each part is identical, a necessary advantage in modern mass production. This level of consistency, paired with its ability to handle complex shapes and tight tolerances, sets CNC punching apart from other metal punching processes.

Want to Outsource Your Punching Operations?

CNC punching is an essential fabrication method in today’s manufacturing landscape, offering precision, efficiency, and versatility across many industries. The ability to produce high-quality, high-speed custom metal components makes CNC punching a go-to solution for manufacturers of all sorts. At JC Metalworks, we take pride in delivering precision-engineered parts through our advanced CNC punching services, working with the highest standards of quality and reliability for every project.

Whether you need a single prototype or mass production, our team of experts is ready to help bring your designs to life quickly and accurately. Contact us today at 01509 233280 to learn more about how our CNC punching services can meet your fabrication needs.