Your Guide to EV Charger Components

An EV Charger comprises many diverse components. When shopping for an electric vehicle charger for the first time, all of the technical jargon can feel quite overwhelming. This guide keeps all of the terminologies simple and straightforward, helping to ensure you get precisely what you want in your new charging equipment.

What are the components of EV chargers?

EV components were first defined in 2011 by the European Automobile Manufacturers Association, also referred to as the ACEA. This is the main lobbying and standards group of the automobile industry in the European Union. Here’s an easy guide to understanding the inner workings of EV charging solutions:

Car charging socket

The first component to know about is the socket, which supplies electrical energy (the charge) from the electric vehicle supply equipment (EVSE) to the vehicle. Vehicles can have up to two charging sockets per charging station.

Type 2 is the most popular for single-socket cars and is the standard socket type throughout Europe. This makes it compatible with just about any car.

Where two sockets are fitted, your car will feature a combination of Type 1 or Type 2 sockets. You can still opt for slow or fast charging as well as a CHAdeMO (Charge for Moving) or CCS (Combined Charging System) socket for DC rapid charging.

We talk about the different ‘types’ in our Frequently Asked Questions post if you’d like to know more.

Electric car plug

This is how the car gets ‘plugged in’ to charge, and is located at the end of the flexible cable connected to the socket outlet. There are two types of AC plugs:

AC type 1 is a single-phase plug and is standard for EVs made, and designed for use, in America and Asia. This allows the car to be charged at a speed of up to 7.4 kW, depending on the charging power of the vehicle and the capability of the grid system.

AC type 2 is a triple-phase plug and is standard for electric cars and vehicles made, and designed for use, across Europe and Asia. These offer power levels of 43 kW.

EV charging cable

The Cable is the flexible bundle of conductors that connects the vehicle with the electric vehicle supply equipment. Portable charging cables that match the vehicle’s connector type are available, allowing drivers to charge their electric vehicle on the go by connecting to public charging stations.

EV charging connector

Finally, the connector is the end of the flexible cable that communicates with the vehicle inlet – the port on the vehicle that receives the electrical energy.

When you know the terminology and the role of the components of EV charging stations, investing in a new station feels a lot more simple.

What are the main components of EV charger design?

A well-designed and built EV charging station should last customers – whether individuals or businesses – for years, with minimal maintenance. The four physical segments of EV charger design are the casing, cabling, electronics and storage. All play a part when shopping for charging equipment. Let’s take a closer look at these:

EV charging station casing

The design of the casing, or enclosure, is a combination of practical, pricing and aesthetic decisions.

Designed to be an outdoor product, the charger requires an Ingress Protection Rating (also known as International Protection Rating or IP Rating). This proves the effectiveness of electrical enclosures – confirming their capabilities of blocking potentially dangerous foreign bodies such as dust, moisture, liquids, and accidental contact.

Electric vehicle charger power cord

The cable or power cord in an EV Charger station not only carries high currents between the vehicle and the charger but also looks after ‘communications’ between the two.

Chargers can be created with tethered or untethered cables. Tethered is generally more convenient but means that the charger is locked to a specific type of connector. Untethered cables are more flexible, allowing users to have a cable that matches their car.

Both are viable options, however, untethered cables require a locking mechanism – so bear this in mind.

In addition to the external cabling, there will also be internal cabling that needs to be accounted for in the mechanical design, as the power requirements mean it can be bulky.

Electronics

An AC charger is essentially a power switch that communicates between the vehicle and the charger. Its main purpose is to ensure electrical safety, with the ability to limit the power that the vehicle takes.

The other key component required for a simple AC smart charge point is a communications controller, often found in single-board computers.

Smart chargers add communications to the charger to sync it with a cloud-controlled network. There may also be extra boards to control displays, authorisations and more, depending on the sophistication of the system.

Advice: Bear in mind that the socket, relays and contactors heat up when on full charge. Heating can shorten component life and the socket is particularly vulnerable as it is exposed to the elements and constant use will cause wear.

EV power storage

The power storage system at an Electric Vehicle Charging Station consists of three main units: Battery, Power Conversion System, and Software.

Battery: Primarily, lithium-ion batteries are used in charging stations compatible with most electric vehicles. A lithium-ion (or Li-ion battery) is a type of rechargeable battery which uses the reversible reduction of lithium ions to store energy. It is the predominant battery type used in portable consumer electronics and electric vehicles.

Power Conversion System: The power conversion system for the EV charging station consists of an inverter, its enclosure, and thermal management (HVAC) to maintain the battery at a specific temperature.

Software: The software is an integral part of EV charging infrastructure. It helps charge point operators and e-mobility service providers manage EV charging stations and best serve their customers. EV charging software (either web or mobile-based) helps to manage the EV chargers at charging stations.

One of the key purposes of the EV charging software is to connect and monitor the charger. In addition to this, it provides a system of automatic fault detection and live meter display, together with billing and payments.

Tracking costs, managing users and providing an interactive dashboard are among other features of EV Charging software.

What to consider when buying electric vehicle supply equipment

One of the first decisions to be made when shopping for an electric vehicle charging station is the size. This varies most with the number of sockets and the power of the charger. Other decisions will also have to be made, such as:

How will it be installed?

Are you looking for a wall-mounted or standing system? It’s worth taking some time to consider the installation process and what will work best for your business or home.

How will you counter extreme temperatures?

This question is likely more important for vehicles that will be taken abroad, although with the heatwaves we have experienced in the UK in recent years, it’s worth thinking about if you’re keeping your car in this country too. As mentioned earlier, certain components are at risk of overheating – so be sure to locate your electric vehicle charging station in a temperature-controlled environment.

Do you want your charge points to blend in or stand out?

While the overall design can be simple, there is also the opportunity to get creative. If you’re looking for something branded or that will have a little pop to it, this is certainly an option as well as opting for a more discreet, compact design.

What amount of security protection will be needed?

If you are purchasing charging infrastructure for your garage, you may not need to worry too much about security. However, if your charger is going to be installed on a street or at large or small workplaces, you may need to think about how you protect your chargers from being used by outsiders, strangers, or the general public.

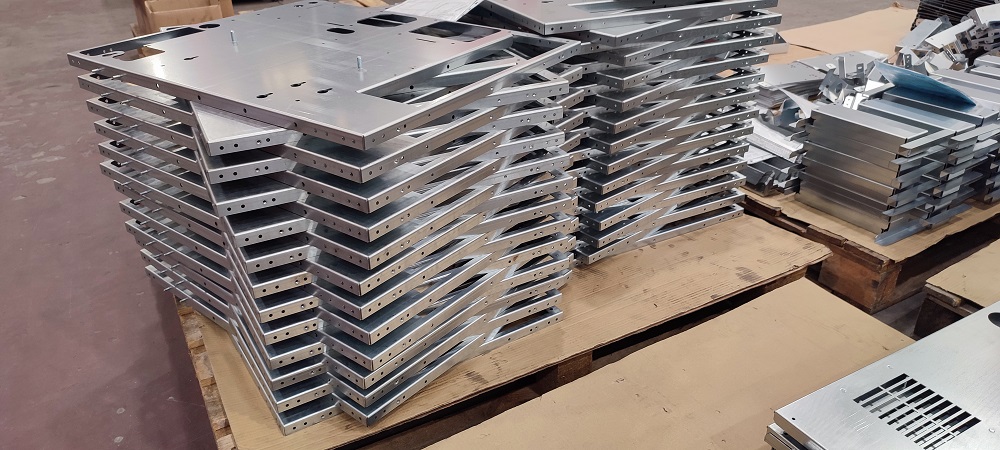

JC Metalworks can manufacture your EV charging systems

Whether you’re in the market for one or multiple EV chargers, we can use our years of design, prototyping, fabrication and assembly knowledge and experience to deliver exactly what you’re looking for.We can help you figure out precisely what you need and get it made and delivered to you for a great price. Find out more or get in touch for a quote.

Leave a Reply