Introduction

Over the past few years, battery storage systems have become increasingly popular. These systems are essential for integrating renewable energy, maintaining grid stability, and providing backup power. This blog post will discuss some common challenges during battery storage enclosure installation and integration and provide strategies to overcome them.

Space Constraints and Siting Challenges

Limited space availability is often a primary challenge when assembling battery storage enclosures. Many installations must fit within the existing infrastructure or confined areas while meeting safety requirements, maintaining accessibility, and accommodating necessary equipment and ventilation systems. To overcome these limitations, careful planning and design are critical. Conduct a thorough assessment of available space and consider alternative options for installation, such as rooftop or wall-mounted placements—Utilise 3D modelling software to visualise the enclosure placement and ensure efficient space utilisation. Also, consult local regulations and safety standards to ensure compliance with setback requirements and other safety considerations.

Cooling and Ventilation

It is essential to provide appropriate cooling and ventilation in battery storage enclosures to maintain optimal operating conditions and prevent safety hazards. Poor cooling may decrease battery performance and lifespan. Active cooling systems are recommended to address these issues. Conduct a thorough analysis of the battery’s heat dissipation characteristics and design ventilation systems that effectively remove excess heat. Install temperature and airflow monitoring mechanisms to detect potential issues early.

Fire Safety and Thermal Runaway

When dealing with battery storage systems, it’s essential to prioritise fire safety. Although it’s not common, the possibility of thermal runaway should be addressed during installation and integration. Thermal runaway can happen due to battery cell damage, internal short circuits, or external factors like extreme temperatures.

To minimise the fire risk, follow recognised fire protection standards and codes. Installing appropriate fire suppression systems can help. Implementing monitoring and thermal monitoring systems that can detect and respond to abnormal temperature increases is also essential. Spacing between battery racks and fire-resistant materials can minimise the spread of fires.

Electrical System Integration

When integrating a battery storage system with existing electrical infrastructure, challenges may arise regarding voltage compatibility, control system interfaces, and protection coordination. It’s essential to design the battery storage system to meet the voltage and frequency requirements of the electrical grid or specific application and consider using power conditioning equipment to regulate and stabilise electrical output. Collaboration with system integrators and electrical engineers can help develop an integrated control system to ensure seamless communication between the battery storage system and other components.

JC Metalworks can be crucial in addressing the common challenges in assembling and integrating battery storage enclosures. Here are some ways in which JC Metalworks can assist:

Customised Enclosure Design and Fabrication

We specialise in custom metal fabrication, including battery storage enclosures tailored to your needs. Our skilled engineers work closely with clients to understand their limitations, safety considerations, and integration needs. We can create prototypes to visualise the enclosure design and ensure efficient use of space.

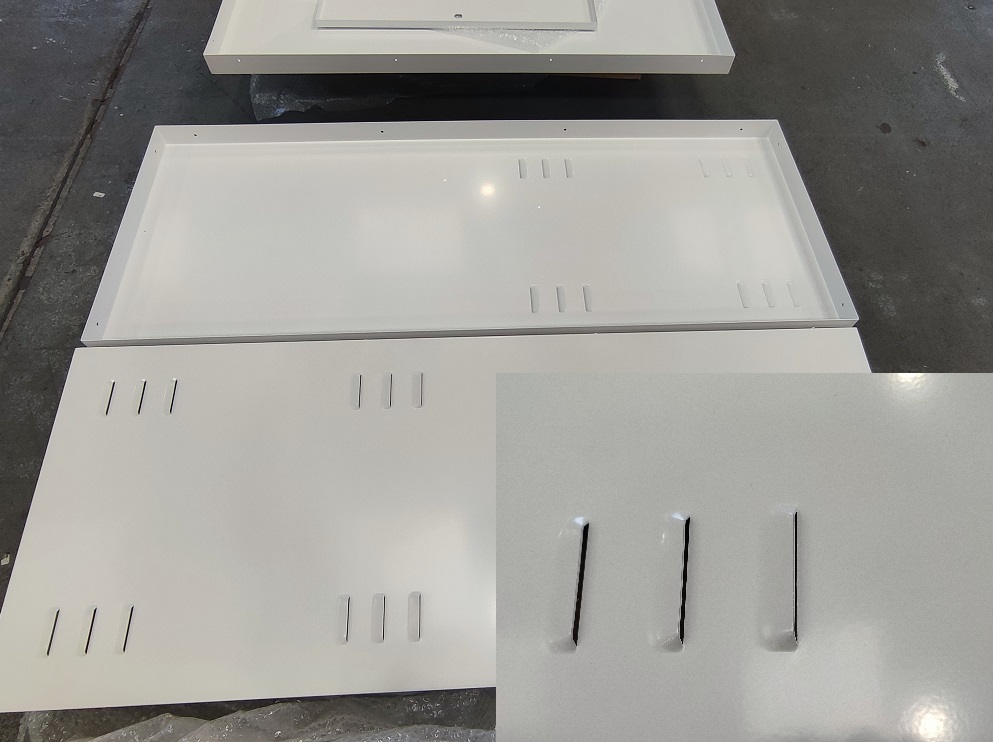

Expertise in Ventilation and Cooling Systems

We are experienced in creating efficient ventilation and cooling systems for different purposes. We can assist you in selecting and installing suitable cooling devices, including fans, heat exchangers, and air conditioning units. Our team’s expertise guarantees that battery storage compartments have sufficient cooling to prevent thermal runaway and enhance battery efficiency.

Compliance with Safety Standards

We prioritise safety regulations and industry standards. Our manufactured battery storage enclosures meet required fire protection standards and codes, with appropriate fire suppression systems and fire-resistant materials incorporated to minimise fire risks. You can trust us to ensure the safety of your products.

Integration with Electrical Infrastructure

We work with electrical engineers and system integrators to ensure battery storage systems can be smoothly integrated with existing electrical infrastructure. We assist in designing and creating components that ensure proper voltage compatibility, control system interfaces, and protection coordination. Our expertise guarantees seamless communication and operation of battery storage systems within overall electrical systems.

Quality Assurance and On-time Delivery

JC Metalworks takes pride in delivering top-notch products within the specified timeframe. We have implemented strict quality control procedures to guarantee that our battery storage enclosures meet all required standards and specifications. Thanks to our efficient manufacturing capabilities, we can meet project deadlines and ensure that installation and integration occur on schedule.

Clients can use JC Metalworks’ expertise and capabilities to obtain custom design, fabrication, and integration services. The company’s dedication to quality and adherence to safety standards can help address the difficulties related to battery storage enclosure assembly and integration.

Conclusion

Assembly and integrating battery storage enclosures can be challenging due to various factors that require careful attention, such as limited space, ventilation, fire safety, and electrical system integration.

Adhering to safety standards and consulting with experienced professionals and local regulations can help maximise battery storage systems’ performance, reliability, and safety. Overcoming these challenges is crucial to unlocking battery storage systems’ full potential and contributing to a sustainable and resilient energy future.

Read more about the topic:

Installing Electrical Energy Storage Systems and Batteries

Regulations: batteries and accumulators

Using electric storage

batteries safely

Leave a Reply