Modern HVAC systems are no longer just “machinery”—they are intelligent, high-efficiency assets that require superior protection. In an era of stringent environmental regulations, the enclosure has evolved from a simple metal box into a critical, precision-engineered component.

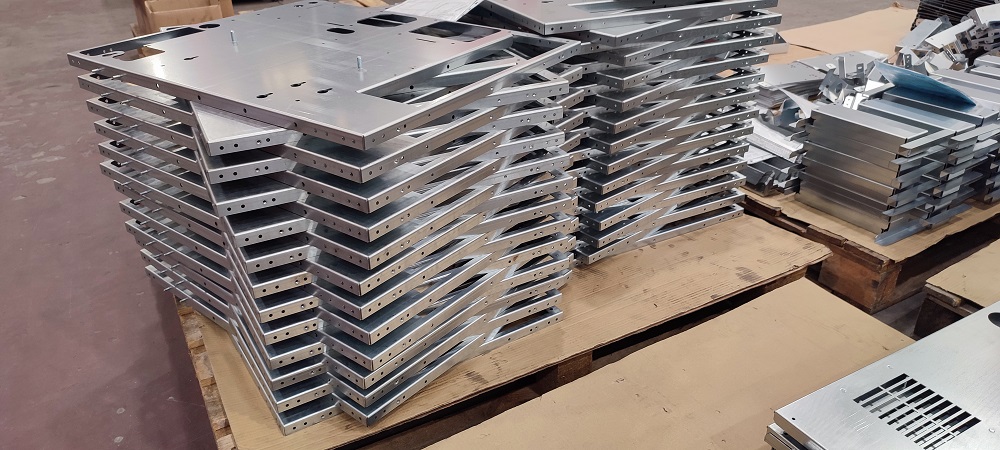

At JC Metalworks, we specialise in HVAC enclosure manufacturing that combines advanced CNC technology with specialised weatherproof metal fabrication. Here is how our integrated process ensures your units withstand the elements while maintaining peak internal performance.

Advanced Fibre Laser Cutting for Complex Geometries

Today’s units require intricate venting and multiple access points for sensors and electrical junctions. Our fibre laser and Automatic Punching technology provides OEM‑grade benefits:

-

- burr‑free, heat‑stable edges for zero secondary processing

- exact reproduction of CAD designs at any scale

- high‑speed profiling for reduced lead times

- precision on thin‑sheet and coated materials

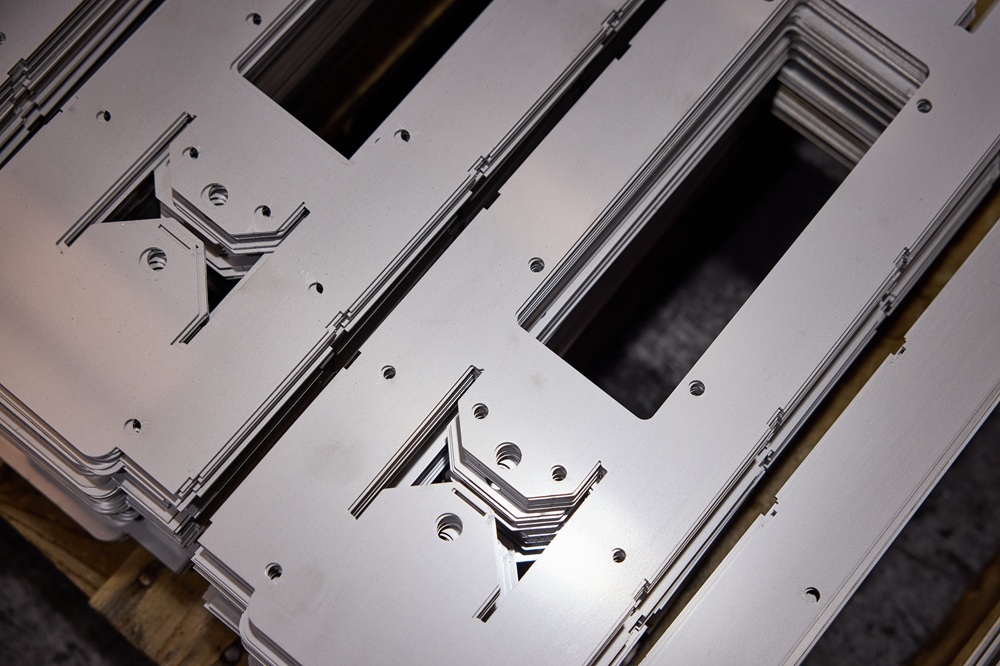

With system miniaturisation and increased electronic integration, HVAC enclosures now require more intricate geometries, including:

-

- complex venting structures

- multi‑depth cutouts for electrical routing

- tight‑alignment mounting features

- access portals for serviceability

- high‑precision airflow slots

OEMs gain predictable, stable manufacturing with minimal risk of fit‑up issues during assembly.

High-Precision CNC Forming

Before an enclosure takes shape, it requires complex folding that accounts for material “spring-back” and structural load. Our CNC forming capabilities provide the skeletal integrity every HVAC unit needs.

-

- By using multi-axis CNC press brakes, we achieve consistent bend angles across thousands of units. This ensures every panel aligns perfectly during final installation, eliminating “forced fits” that lead to stress fractures or air leaks in high-pressure systems.

Robotic Welding for Structural Rigidity

HVAC enclosures face constant vibration, environmental cycling, and mechanical loading. Consistency of weld penetration and bead quality is essential for long-term durability.

JC Metalworks’ robotic MIG/TIG welding capabilities ensure:

-

- Uniform penetration: Delivering stronger, more consistent joints than manual welding can offer at high volumes.

- Weatherproof seams: Clean, consistent beads that serve as the first line of defence against moisture ingress.

- reduced distortion on thin‑gauge steels

- high structural rigidity for rooftop and outdoor applications

- repeatable quality that meets OEM audit standards

- This is critical for OEMs who need reliability not just in one unit, but across entire product lines.

Comprehensive In-House Assembly

We are more than just a parts shop; we are a full-scale manufacturing partner. By managing the in-house assembly process, we act as a seamless extension of your production line. To help OEMs reduce supplier count and accelerate final build, JC Metalworks provides end‑to‑end assembly services tailored to HVAC enclosure requirements

-

- Electromechanical sub‑assembly: fan housings, filter cassettes, damper mechanisms, controller brackets, hinge & latch systems.

- Kitting & line‑side delivery: labelled kits with fasteners, gaskets, cable glands, and fixings to OEM BOM/spec.

- Gasket, seal & hardware installation: precision fitting of compression seals, IP‑rated grommets, latches, and hinges to tolerance.

- Light wiring & loom routing (where specified): clips, grommets, cable management pathways per CAD.

- Functional checks & fit‑up verification: door alignment, torque settings, access panel operation, airflow aperture conformity.

- Documentation: assembly records, serialisation, and traceable sign‑off packs aligned to OEM QA requirements.

- Result: shortened OEM assembly times, reduced rework, and consistent field performance across batches.

Specialist Weatherproof Metal Fabrication & Finishing

Outdoor HVAC systems face rain, UV exposure, and chemical contaminants. We achieve industry-leading weatherproof metal fabrication through:

-

- Material Selection: Expertise in galvanised steel, stainless steel, and architectural-grade aluminium.

- Industrial‑Grade Powder Coating for Long‑Life Corrosion Control: Powder coating is essential for HVAC systems positioned on rooftops, factory floors, and external walls. JC Metalworks’ automated powder‑coating line delivers:

- electrostatically balanced coating thickness

- exceptional adhesion for chip resistance

- even curing for long‑term corrosion control

- colour‑matched finishing to OEM brand standards

- compliance with environmental exposure requirements

- For OEMs, this reduces maintenance cycles and increases service lifespan, even in corrosive or high‑humidity locations.

Precision That OEM Engineers Can Depend On

HVAC systems integrate multiple sensitive components: sensors, PCB assemblies, controllers, compressors, filters, and airflow mechanisms. These demand enclosures manufactured with extremely strict dimensional accuracy.

JC Metalworks supports OEMs with:

-

- Sub‑millimetre CNC tolerances for doors, flanges, mounts & structural profiles

- Repeatable accuracy across high‑volume batches

- Tight‑tolerance bending & forming for airflow optimisation

- CAD‑to‑production digital workflows for error‑free manufacturing

This ensures that every batch performs identically in the field — essential for OEM qualification and compliance.

Why HVAC OEMs Partner with JC Metalworks

As a leader in precision sheet metal work, we support HVAC manufacturers and industrial contractors with:

-

- UK-Based Manufacturing: End‑to‑end UK manufacturing, thus reducing lead times and ensuring rigorous quality control.

- NPI & Prototyping: We help you refine designs for “manufacturability,” ensuring cost-efficiency without sacrificing performance.

- End-to-End Traceability: From the raw material mill certificate to the final assembled unit.

As HVAC technology evolves, your enclosures must deliver more than protection—they must deliver precision.

Looking for a specialist in HVAC enclosure manufacturing? Contact the JC Metalworks team today to discuss your technical specifications or to request a quote for your next production run.