Quick links:

- What is reverse engineering?

- What’s the process as part of product design?

- What’s the process of reverse engineering work?

- What are the benefits of reverse engineering?

What is reverse engineering?

Reverse engineering offers clients a powerful tool for understanding, improving, and innovating upon existing metal components.

What’s the reverse engineering process as part of the product design process?

Reverse engineering is the meticulous process of analysing an existing physical object, in this case, a metal component, to extract its design intent, specifications and functionality.

One of the key techniques we use is scanning, which allows us to capture the precise dimensions and intricate details of the component. It involves meticulously capturing intricate details such as:

- Dimensions: Precise measurements of all aspects of the component, including length, width, height, and any internal features.

- Materials: Identifying the specific metal or alloy used in the component’s construction, crucial for replicating its properties.

- Functionalities: Understanding how the component interacts with other parts of a system and the specific role it plays.

Clients can benefit from reverse engineering in a multitude of ways, both practical and innovative.

What is the process of reverse engineering work?

At JC Metalworks, we are engineering experts who understand the intricacies of reverse engineering metal components. Our team of skilled engineers is adept at reverse engineering, ensuring that every detail is captured accurately. Our process is meticulous and leverages cutting-edge technology to ensure the most accurate results.

Here’s a breakdown of the reverse engineering techniques involved:

1. Capturing comprehensive data

The process begins with a thorough examination of the component. This process is not limited to metal parts; we also capture data from electronic components to ensure comprehensive analysis. Our team may utilise high-resolution photography to capture intricate details and external features. However, this is just the first layer of data acquisition.

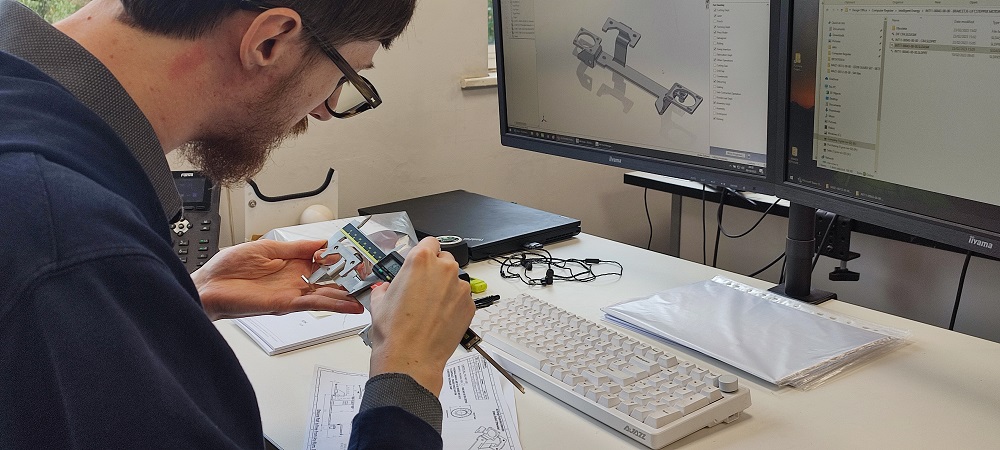

2. Precision measurement and disassembly: Key reverse engineering techniques

We meticulously disassemble the components into their individual parts. This allows for highly accurate measurements using callipers and micrometres for smaller features or tight tolerances. Our engineers may utilise high-precision measuring tools to ensure every dimension is captured with exceptional accuracy.

3. Digital model creation and assembly

Once all the parts have been meticulously measured, our team utilises advanced computer aided design (CAD) software to create detailed digital models of each individual component. Our advanced computer system allows us to create highly detailed and accurate digital models of each component. These models are not simply two-dimensional representations; they are fully functional 3D models that capture the precise geometry and tolerances of each part.

4. SolidWorks assembly and optimisation

The individual 3D models are then imported into a powerful platform like SolidWorks. This allows our engineers to virtually assemble the components, mimicking the physical component’s functionality. This digital assembly not only verifies the accuracy of the individual models but also provides a platform for further analysis.

5. Customisation for production efficiency

Our expertise extends beyond simply replicating a component. We understand the importance of production efficiency. By analysing the digital model and considering our advanced machinery capabilities, our engineers can identify opportunities to optimise the design for manufacturability. This may involve:

- Simplification of complex geometries: We may explore alternative manufacturing methods or slight design modifications that can be achieved with our equipment, ultimately streamlining the production process.

- Standardisation of components: If a component utilises multiple fasteners or parts with slightly different specifications, we may explore opportunities to standardise these elements, reducing complexity and production costs.

What are the benefits of reverse engineering in design engineering work?

Benefit |

Description |

|---|---|

| Product Replication | Recreate components when original manufacturer is unavailable or component is discontinued. |

| Improved Design and Performance | Analyse strengths and weaknesses of existing components to optimize new designs. |

| Material Optimisation | Identify materials used in successful components for potential alternatives. |

| Cost-Effective Manufacturing | Understand manufacturing processes to improve efficiency and reduce costs. |

| Innovation and New Product Development | Inspire new features, functionalities, or products based on existing designs. |

| Troubleshooting and Problem-Solving | Diagnose component issues by understanding internal workings. |

| Shortened Development Time and Reduced Costs | Bypass initial design stages by leveraging existing component knowledge. |

| Identify Efficient Suppliers | Discover suitable suppliers based on component analysis. |

| Respecting Intellectual Property | Adhere to legal and ethical standards when reverse engineering. |

We at JC Metalworks are your trusted partner in the world of reverse engineering. Our expertise, combined with cutting-edge technology and a collaborative approach, allows us to unlock the potential of existing components and transform your vision into a reality.

From the expert

Here’s what Daniel Marriott, Operations Manager has to say about reverse engineering:

Reverse engineering has the potential to significantly impact metal fabrication. It involves taking a physical part and creating an accurate 3D CAD model. The true benefit for our customers lies in the efficiency it provides. The 3D model enables quick assessment of manufacturability and effective design optimization, resulting in precise metal pieces that perfectly match the original component.

Reverse engineering closes the gap between existing parts and their metal fabrication, streamlining the process, reducing errors, and opening doors for design improvements. It is a valuable service for keeping your projects moving forward.

Contact JC Metalworks today to discuss your specific reverse engineering needs and experience the difference.

Leave a Reply