Preventing NPI Failure with Design for Manufacture (DFM)

When UK manufacturers begin a New Product Introduction (NPI), the pressure to finalise robust engineering decisions fast is immense. However, one of the biggest threats to a successful, on-time launch isn’t your internal design capability. It’s choosing a sheet metal fabrication partner that only builds to print, rather than collaborating from the start.

Too many metal fabricators in the UK operate purely as “quote-and-cut” suppliers:

-

- They wait for final drawings.

- They quote without genuinely challenging manufacturability.

- They produce parts exactly as instructed—whether cost-effective or practical.

On the surface, this approach to precision sheet metalwork seems efficient. In reality, it leads to the most damaging and costly NPI issues:

-

- Slow, inefficient prototyping cycles.

- Late-stage redesigns and engineering churn.

- Tolerance stack-up problems in complex assemblies.

- Unmanufacturable designs entering production.

- Escalating project costs and critical NPI delays.

For OEMs and design teams, this lack of early-stage supplier involvement is a massive, costly bottleneck. This is why choosing a trusted UK metal fabricator is more than a purchasing decision—it’s a strategic engineering choice.

At JC Metalworks, we act as a true engineering extension of your team, not just a supplier. We collaborate from concept review to full production, ensuring your sheet metal design is feasible, cost-optimised, and production-ready from day one.

The Hidden Cost of Weak Supplier Involvement in Sheet Metal NPI

The majority of a product’s lifetime cost and manufacturability is locked in during the early development phases. When a sheet metal subcontractor isn’t involved early, or fails to provide critical engineering insight, problems multiply exponentially.

1. Slow, Unproductive Prototype Cycles

Without guidance from an experienced sheet metal fabrication specialist:

-

- Designs are often over-engineered, increasing material and process costs.

- Parts require repeated, time-consuming revisions.

- Incorrect assumptions cause significant, avoidable delays.

- Lead times stretch and launch windows compress.

A prototype that should take days can take weeks because no one with practical manufacturing experience questioned the feasibility of a feature.

2. Tolerance Stack Failures

Sheet metal is not like machined solid block—it moves, flexes, expands, and distorts under heat (welding) and forming (bending). If your fabricator doesn’t offer tolerance advice early, you risk:

-

- Misaligned bracketry and internal components.

- Door and panel misfits that fail to close or seal.

- Unacceptable weld distortion on aesthetic surfaces.

- Assembly issues that only become apparent in a physical, costly build.

These failures almost always stem from a lack of supplier input during the initial design phase, leading to expensive remedial work on your metal assemblies.

3. Manufacturing Crises After Final Sign-Off

When a metal subcontractor avoids telling you “this won’t work,” the explosion happens later—often during high-volume pre-production.

Late-stage manufacturing crises often involve:

-

- Features impossible to form with standard CNC press braking.

- Tight tolerances that are unrealistic or overly expensive for sheet metal.

- Parts that require expensive, slow, or secondary processes.

- Weld geometries that compromise structural integrity or aesthetic finish.

The conclusion is simple: If your sheet metal fabricator isn’t actively steering you early, they’re costing you later in production.

How JC Metalworks Accelerates NPI with an Engineering-First Approach

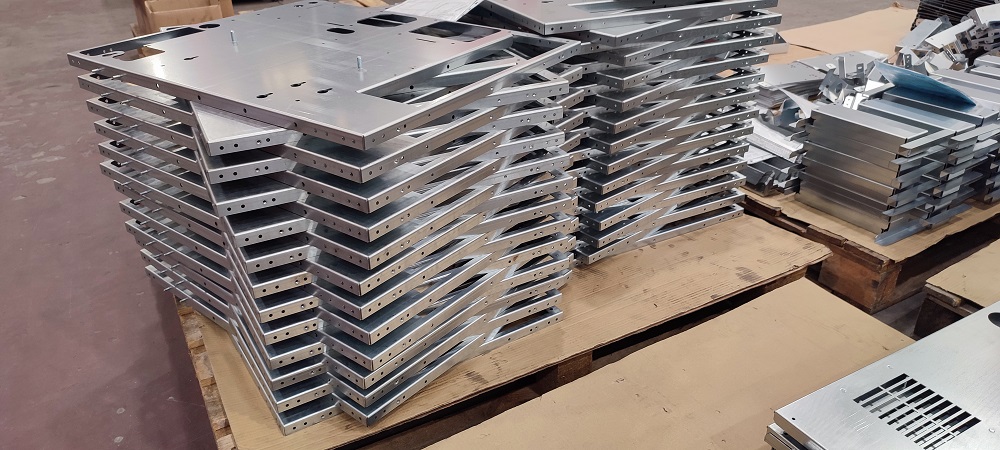

JC Metalworks has become a trusted partner for OEMs by acting as a precision sheet metalwork specialist that supports customers from design concept through to full-scale production.

Here is how our engineering-led approach removes risk and accelerates development for our UK partners:

1. Early Engagement and Design Review

The biggest NPI failures come from suppliers getting involved too late. Our experienced engineers step in early, reviewing the geometry against our fabrication capabilities, focusing on:

-

- Design for Manufacture (DFM) principles.

- Material utilisation and optimisation.

- Bend allowances, radii, and hole-to-edge distances.

- Welding strategy and finishing requirements.

- Overall assembly fit and tolerance logic.

Our role is to challenge the drawing before it becomes a costly physical problem.

Outcome: Fewer revisions, fewer surprises, and a significantly smoother NPI process.

2. Fast, Insightful Prototype Loops

Our comprehensive UK facility allows us to turn around prototype parts rapidly, controlling the process completely:

-

- In-house laser cutting.

- CNC press braking.

- MIG & TIG welding.

- Assembly and final powder coating/finishing.

Crucially, speed is paired with structure. We provide detailed feedback on every prototype, highlighting immediate manufacturability improvements and cost-saving opportunities. This ensures the design is optimised for efficient production sheet metal fabrication when it becomes final.

3. Industry-Leading DFM Support

Design for Manufacture (DFM) is where JC Metalworks truly excels. We help customers improve:

| Area of Focus | JC Metalworks’ DFM Advantage |

| Cost | Optimise material cuts and reduce expensive processes. |

| Part Strength | Refine bend design and material selection. |

| Assembly | Reduce part count and simplify weld positioning. |

| Cosmetics | Ensure finish consistency and minimal distortion on critical surfaces. |

Often, a simple 2–3 mm design change can save months of future headache—if your supplier has the engineering capability to spot it.

4. Full In-House Production: The Seamless NPI Process

Because we offer fabrication, welding, powder coating, assembly, packaging, and delivery all under one roof, we control the full manufacturing lifecycle.

This single-source accountability means:

-

- No fragmented supply chain.

- No finishing delays or inconsistent outcomes.

- No transport damage between multiple suppliers.

- Full documentation control and traceability.

Partner with the UK’s Most Trusted Metal Fabricator

By partnering with JC Metalworks, you gain a strategic advantage:

-

- Shorter NPI cycles and faster time-to-market.

- Lower production costs through DFM optimisation.

- Predictable production readiness and consistent quality.

- Fewer engineering surprises and costly redesigns.

We don’t just fabricate; we engineer success into your product before metal ever gets cut.

Ready to Optimise Your Sheet Metal Product? Get in Touch.

To start a discussion about your current sheet metal fabrication requirements, DFM review needs, or complex metal assemblies, please contact our team directly:

📧 Email: [email protected]

We look forward to partnering with you as your trusted UK sheet metal fabricator and engineering extension.