At first glance, a metal box may seem like a simple, standard component—just folded sheet metal with a few welds. But behind its seemingly basic appearance lies a true test of precision engineering, material science, and advanced fabrication capability. The metal box poses a challenge even to the most experienced fabricators when it must meet demanding tolerances, environmental ratings, hygiene standards, or military specifications. Despite having a single core form, metal boxes are used across a vast range of industries—each with its own performance, regulatory, and durability requirements. From housing sensitive electronics to withstanding marine corrosion or maintaining sterile conditions in pharmaceutical environments, the fabrication of a metal box is a showcase of both versatility and expertise.

When it comes to metal enclosures and box fabrication, precision in welding and forming is critical—regardless of whether the box is made from stainless steel, aluminium, galvanised steel, or mild steel. These aren’t just “boxes”—they’re engineered housings that protect critical components, ensure regulatory compliance, and withstand harsh operating conditions.

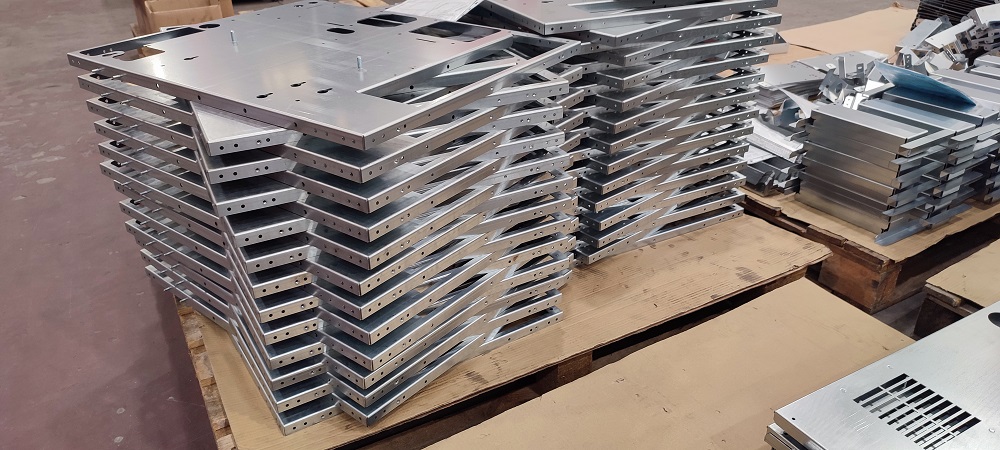

At JC Metalworks, we specialise in the precision fabrication of metal boxes across multiple industries and materials, with deep expertise in:

- Stainless steel (304, 316L, 430)

- Mild steel (CR4, S275, S355)

- Aluminium (1050, 5251, 5083)

- Galvanised and Zintec steel

This blog details why precision in metal forming and welding matters—and how JC Metalworks tailors solutions to meet the performance, hygiene, and regulatory needs of each sector.

Why Precision in Welding & Forming Is Non-Negotiable

Regardless of material, precision fabrication matters for:

Dimensional Tolerances

- Tight tolerances ensure components fit correctly and boxes seal properly.

- Precision CNC forming minimises cumulative error in multi-part assemblies.

Structural Integrity

- Poor weld penetration or warped bends can lead to fatigue, cracking, or failure.

- Precision welding (TIG, MIG, robotic) provides structural consistency.

IP & Environmental Sealing

- Enclosures often require IP-rated protection (IP65–IP67).

- Accurate bending and welding is essential for gasket performance and seal retention.

Cleanability & Sanitation

- Food, pharma, and medical boxes require smooth, crevice-free welds and radiused corners.

- Surfaces must be cleanable using CIP or high-pressure washdown methods.

Aesthetic & Brand Quality

- Visible surfaces in retail, foodservice, or consumer devices require clean welds and consistent surface finishing.

Regulatory Compliance

- Meeting Industry standards depends on precision documentation, repeatability, and finish quality.

JC Metalworks: Multi-Material Fabrication Capabilities

Materials Expertise

| Material | Benefits | Common Uses |

| Stainless Steel (304/316L) | Corrosion-resistant, hygienic, long-lasting | Food, pharma, medical, marine |

| Mild Steel (CR4, S275) | Cost-effective, strong, weldable | Electrical, retail fixtures, security housings |

| Aluminium (5083, 5251) | Lightweight, corrosion-resistant, excellent conductivity | Electronics, marine, aerospace |

| Galvanised / Zintec Steel | Rust-resistant, economical | Outdoor housings, HVAC boxes, infrastructure |

Precision Fabrication Processes

| Process | Equipment |

| Laser Cutting & Punching | Amada fibre lasers (up to 20 mm stainless, 15 mm mild steel) |

| CNC Bending | Multi-axis press brakes (±0.5° accuracy) |

| Welding | Laser, TIG, MIG, robotic MIG, spot welding (steel, stainless, aluminium) |

| Finishing | Brushing, powder coating, mirror polishing and electropolishing |

| Assembly | Hinges, PEM fasteners, seals, access doors, and electronics integration |

Quality Assurance

- ISO 9001:2015 certified

- Weld procedure specs (WPS), inspections, and traceability

- Full dimensional reporting and finishing audits

Industry Use Cases: Precision metal fabrication needs by Sector

Here’s how JC Metalworks applies material-specific precision to deliver performance in five high-demand industries:

Defence & Military

Materials Used: Mild steel, stainless, aluminium

Why Precision Matters:

Precision Methods:

- CNC-formed mild or stainless steel plates

- Laser and Robotic MIG welding for repeatability

- Powder-coated or anodised finishes for corrosion and wear

Failure Impact: Compromised field equipment, loss of tactical capability

Electrical & Electronics

Materials Used: Mild steel (Zintec), aluminium, stainless steel

Why Precision Matters:

- Tight bends and IP-rated seals are critical for internal electronics

- Grounding and EMI/RFI control rely on clean joining and surface conductivity

Precision Methods:

- Laser-cut slots for cable glands and connectors

- Seam-welded housings with fitted gasket grooves

- Conductive coatings or chromated aluminium finishing

Failure Impact: Short-circuits, system failure, regulatory non-compliance

Pharmaceutical & Biotech

Materials Used: Stainless steel

Why Precision Matters:

- Crevice-free welds and sanitisable surfaces prevent microbial contamination

- Precision forming ensures radiused corners, no dead zones

Precision Methods:

- Orbital or TIG welds with full penetration and post-polishing

- Electropolishing

- Designed to meet REQUIRED standards

Failure Impact: Product contamination, failed audits, production shutdowns

Food & Beverage

Materials Used: 304/316L stainless, aluminium for lightweight units

Why Precision Matters:

- Clean-in-place (CIP) compatibility

- No sharp edges or weld undercuts that trap food particles

Precision Methods:

- TIG welding with sanitary finishing

- Formed sloped tops and drainable bases

- Compliant housing profiles

Failure Impact: Food contamination, safety violations, brand damage

Marine & Offshore

Materials Used: 316 stainless, aluminium, powder-coated mild steel

Why Precision Matters:

- Must resist salt spray, pressure, vibration, and UV

- Watertightness and galvanic compatibility are critical

Precision Methods:

- Tested welds

- Seamless gasket channels and precision-cut vents

- Anodised aluminium or passivated stainless steel

Failure Impact: Electrical failures, corroded structures, costly downtime

JC Metalworks = One Partner, All Solutions

| Capability | Detail |

| Multi-material production | Stainless, mild, galvanised, aluminium |

| Full-service | CAD/CAM design to assembly and delivery |

| Sector-certified | specification readiness |

| Clean & precise | Sanitary welding, IP-rated forming, decorative finishing |

| Batch to high-volume | Prototyping, production scaling, repeatability |

Build Your Next Precision Metal Enclosure with JC Metalworks

From sealed electrical housings to sanitary pharma enclosures, JC Metalworks delivers material-specific, industry-compliant, precision-engineered boxes to some of the UK’s most demanding sectors.

Visit jcmetalworks.co.uk or contact us today to discuss your stainless, aluminium, or steel box project.