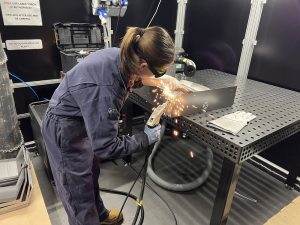

Precision Laser Welding for Superior Metal Fabrication

At JC Metalworks, we specialise in high-precision laser welding, delivering exceptional quality and efficiency for even the most demanding metal fabrication projects. Our latest investment in two state-of-the-art FIBRE LASER welding systems has expanded our capabilities, adding two additional bays. This brings our total to 19 cutting-edge welding bays, ensuring we meet your fabrication needs with precision, speed, and consistency.

Why Laser Welding Outperforms Conventional Welding

Unlike conventional welding methods, laser welding offers incredible precision and strength. It’s a transformative technology that ensures every project we undertake meets the highest standards, no matter how complex or demanding.

So, what makes laser welding superior? Here are 10 reasons why it’s the go-to choice for advanced metal fabrication:

Fast Welding Speeds: Laser welding is up to 4 times faster than traditional TIG welding, which means quicker turnaround times for your projects.

Minimal Heat-Affected Zone: The precision of laser welding ensures that only the targeted area is heated, protecting the integrity of the surrounding material.

Minimal Material Distortion: Reduced heat means less warping, preserving the original shape and dimensions of your components.

High Precision and Neat Welding Seams: Say goodbye to rough edges and inconsistent welds. Laser welding produces clean, uniform seams.

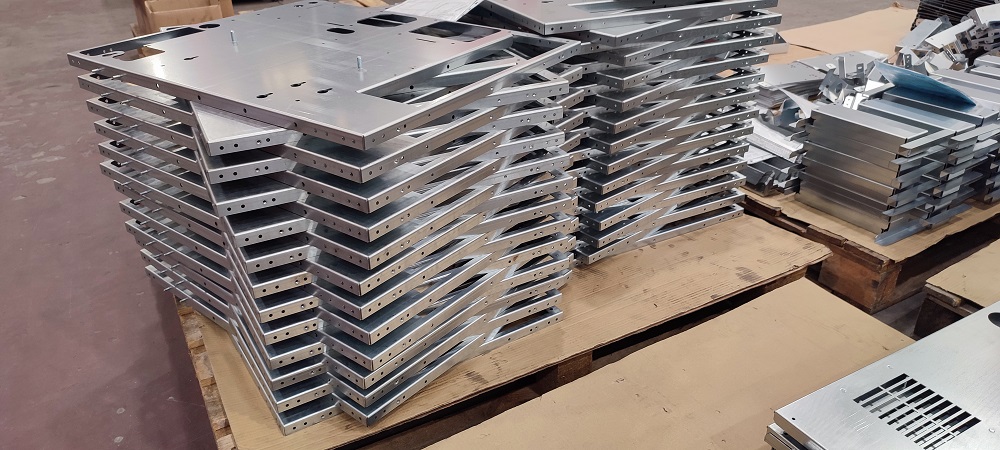

High Repeatability: Consistent results every time, making laser welding ideal for mass production and intricate designs.

Uniform Weld Bead: A flawless finish that enhances your products’ visual and structural quality.

Ability to Weld Various Materials: From aluminium to steel, and even 2 different materials, laser welding handles it all.

Reduced Post-Weld Linishing Times: Clean seams eliminate the need for extensive finishing work, saving time and labour costs.

High Welding Strength: Laser welds are neat and incredibly strong, ensuring durability and reliability.

Boosted Overall Product Quality: Superior welds mean superior products, giving you a competitive edge in the market.

How JC Metalworks’ Clients Benefit from Laser Welding

Increased Efficiency:

Speed matters in today’s fast-paced market. Our laser welding systems significantly cut production times, helping you meet tight deadlines without compromising on quality.

Superior Quality Products:

A clean, strong weld not only looks great but also performs better. The precision of our laser welding ensures every product is crafted to perfection, boosting your brand’s reputation.

Cost Savings:

Minimal post-weld finishing and faster production times, also reduced consumable usage, you’ll enjoy significant savings in both time and money.

Versatility:

From intricate designs to heavy-duty components, our laser welding systems handle a wide variety of materials and applications, ensuring we can meet your unique needs.

Sustainability:

Energy-efficient technology and reduced waste align with growing environmental targets, helping you stay ahead of industry trends and regulations.

Ready to Transform Your Projects: Choose JC Metalworks for your metal fabrication services.

When you choose JC Metalworks, you’re selecting more than just a metal fabricator; you’re partnering with a team dedicated to innovation, quality, and client satisfaction. Our commitment to advanced technology demonstrates our desire to deliver the best for our clients. With 19 state-of-the-art welding bays, including TIG, MIG, SPOT, and robotic welding systems, along with our two new fibre laser welding systems, we are equipped to handle projects of any size with exceptional precision and speed.

If you are looking for a sheet metal fabrication company in the UK that can provide you with high-quality, efficient laser welding services, please contact JC Metalworks today. We would be happy to discuss your project and provide you with a quote.